Product

Full granulation function and high production efficiency

Roller granulator extrusion granulation fertilizer production line

Product Despriction

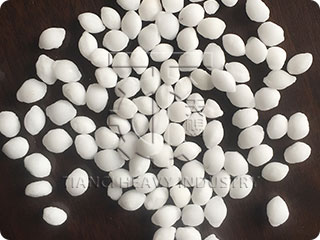

The extrusion granulation production line is widely used in the production of compound fertilizer granules, mainly used to produce spherical granules with a diameter of 1mm-5mm.

Wide adaptability of raw materials, can be used for granulation of various raw materials such as compound fertilizer, medicine, chemical industry, feed, etc., high granulation rate, can produce various concentrations, various types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer etc.) compound fertilizer.

Raw Materials

Compound fertilizer is the fertilizer containing two or all three of the three basic plant nutrients—Nitrogen, Phosphorus, and Potassium, as well as microelements, such as B, Mn, Cu, Zn, and Mo. The raw material can be powder or bulk, mostly are as below:

|

Nitrogen |

Phosphorus |

Potassium |

|

|

Calcium nitrate |

urea |

Single superphosphate |

Kainit |

|

Ammonium bicarbonate |

Ammonium chloride |

Rock phosphate |

Potassium chloride |

|

Nitrate of soda |

Ammonium sulphate nitrate |

Dicalcium phosphate |

Potassium sulphate |

|

Ammonium sulphate |

Ammonium nitrate |

Triple superphosphate |

Potassium nitrate |

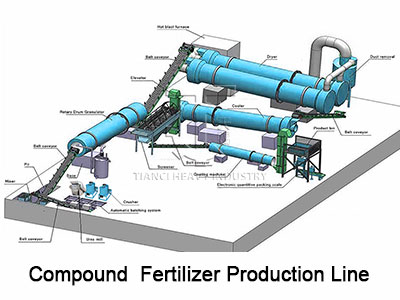

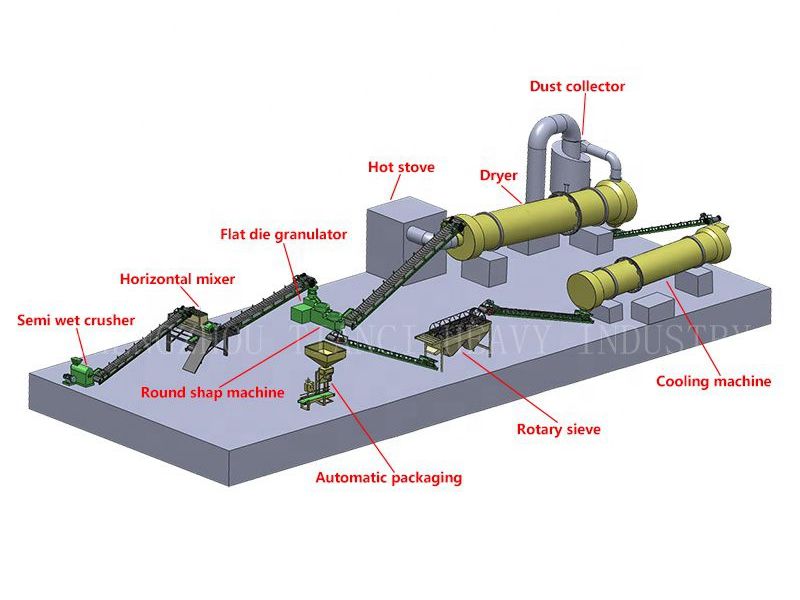

Main Equipments Of NPK Compound Fertilizer Making Production Line

|

No. |

Processes |

Machines |

Function of machines |

|

1 |

Crushing process |

Crusher |

Crushing granules to powder |

|

2 |

Mixing process |

Mixer |

It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation. |

|

3 |

Granulating process |

Disc feeder |

for offering the raw material to the granulator evenly. |

|

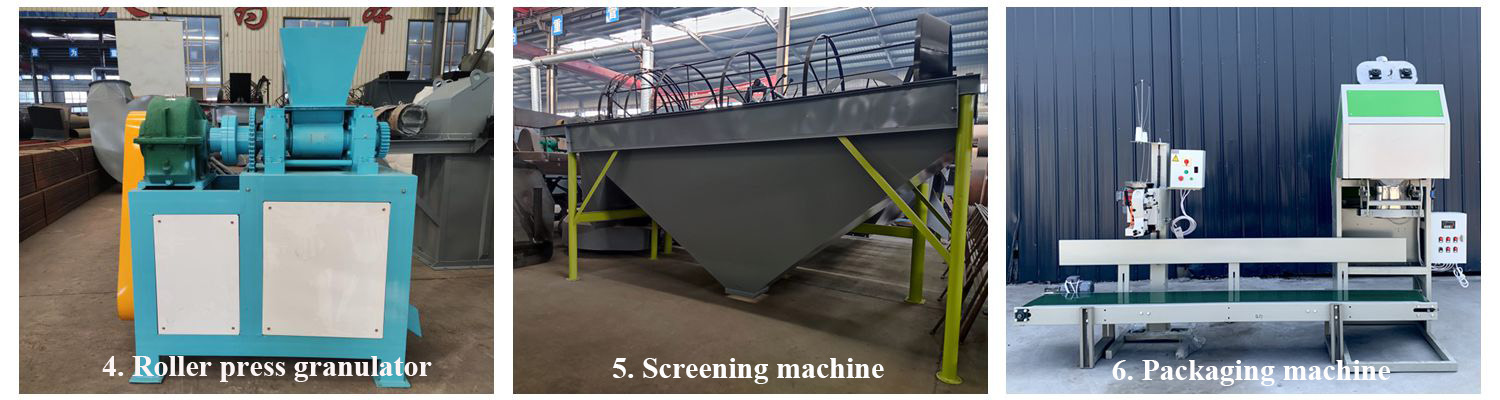

Roller press granulator |

Make mixed powder into fertilizer granules |

||

|

4 |

Screening process |

Rotary screener |

used for the separation of finished products and returned materials |

| 5 |

Packing machine |

Packaging machine |

Package fertilizer granules into bags |

Working Project

Delivery

Package : Full 20GP or 40HQ container by sea or train

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932