Product

Full granulation function and high production efficiency

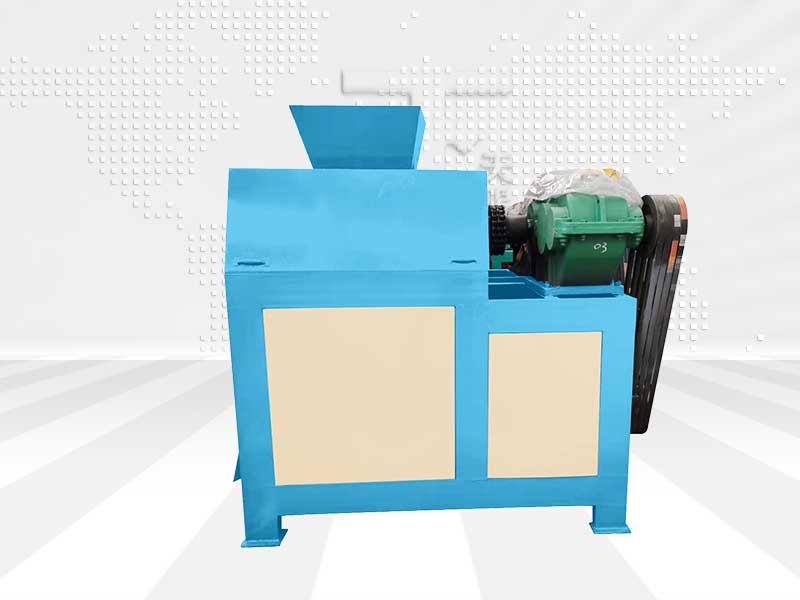

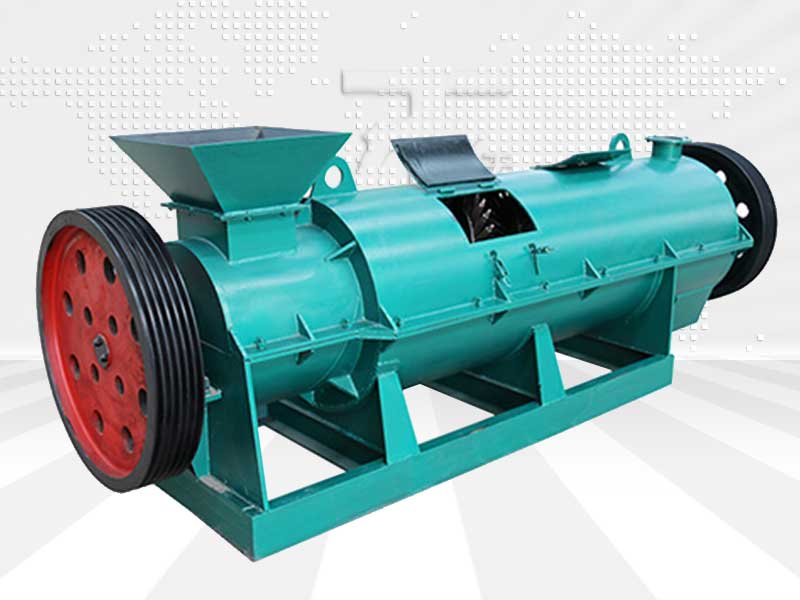

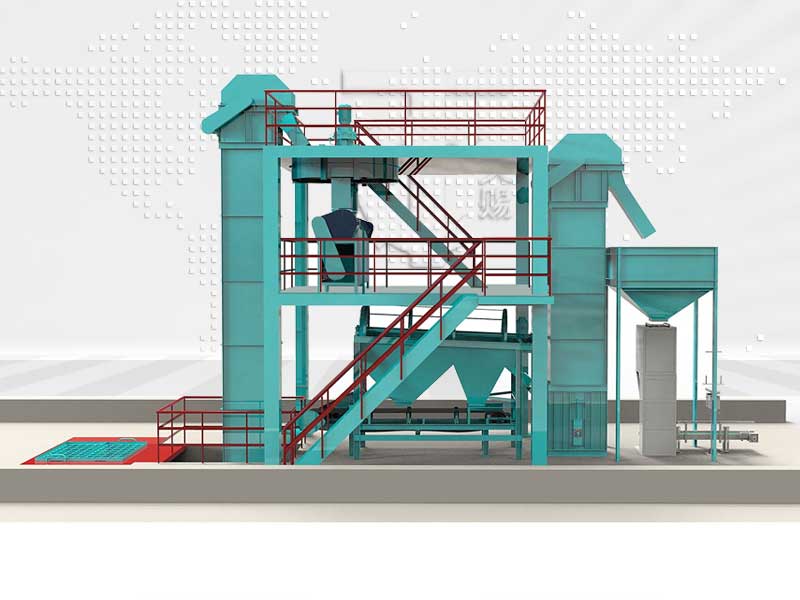

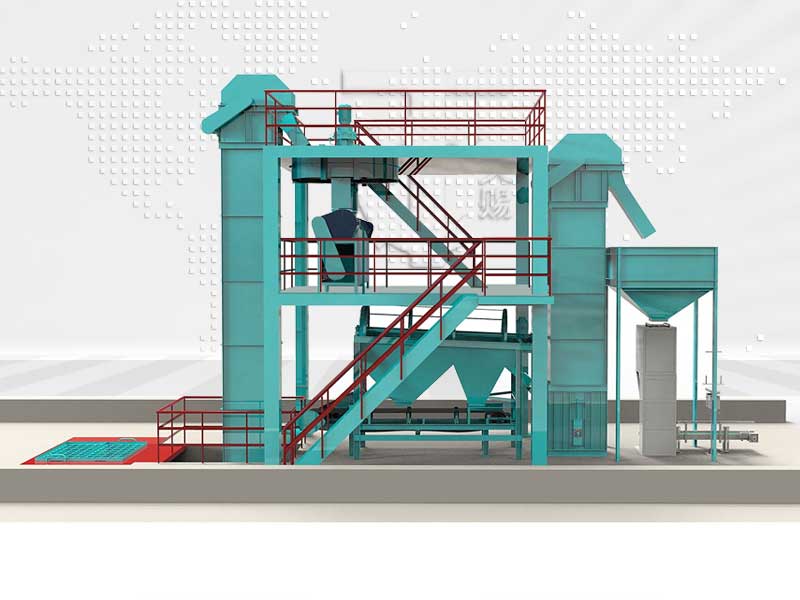

2022 New Style Raw Materials For Organic Fertilizer - Roller press granulator production line – Tianci

2022 New Style Raw Materials For Organic Fertilizer - Roller press granulator production line – Tianci Detail:

Raw Materials and Main Equipments

Raw Material For NPK Compound Fertilizer Making Production Line

Compound fertilizer is the fertilizer containing two or all three of the three basic plant nutrients—Nitrogen, Phosphorus, and Potassium, as well as microelements, such as B, Mn, Cu, Zn, and Mo. The raw material can be powder or bulk, mostly are as below:

|

Nitrogen |

Phosphorus |

Potassium |

|

|

Calcium nitrate |

urea |

Single superphosphate |

Kainit |

|

Ammonium bicarbonate |

Ammonium chloride |

Rock phosphate |

Potassium chloride |

|

Nitrate of soda |

Ammonium sulphate nitrate |

Dicalcium phosphate |

Potassium sulphate |

|

Ammonium sulphate |

Ammonium nitrate |

Triple superphosphate |

Potassium nitrate |

Main Equipments Of NPK Compound Fertilizer Making Production Line

|

No. |

Processes |

Machines |

Function of machines |

|

1 |

Batching process |

Automatic batching machine |

Ratio raw materials by formula |

|

2 |

Grinding process |

Grinder |

Grind granules to powder |

|

3 |

Mixing process |

Mixer |

Mix powder evenly, If necessary, add water, or other micro-elements |

|

4 |

Granulating process |

Feeding machine |

Feed mixed powder into granulator evenly |

|

Granulator |

Make mixed powder into fertilizer granules |

||

|

5 |

Screening process |

Screener |

Screen out required size from fertilizer granules |

|

6 |

Coating process |

Coating machine |

Coat color, anti-blocking agent, microelements etc on fertilizer granules |

|

7 |

Packaging process |

Air compressor |

Generate power to packaging machine |

|

Packaging machine |

Package fertilizer granules into bags |

Advantages

Productive Technology: this machine by the process of high temperature drying, disinfection, decomposition and dried can make fresh chicken which moisture is 65% becomes pure organic chicken which moisture is below 13%.

Drum drying have high mechanization degree, bigger production capacity, can run continuously.

Final Products: the organic fertilizer has many kinds of necessary nutrients for the crops. After scientific research departments detection: the fertilizer of nitrogen content is 2.6%, the phosphorus content is 3.5%, potassium content is 2.5%, crude protein content is 16-25%, organic matter content is 45%. is the best choose fertilizer for planting pollution-free green food , can also used for feeding the fish, cattle, pigs, etc.

Structure is good and simple, material through the resistance of barrel, easy to operate.

Less malfunction, lower maintenance cost, low power consumption.

Widely used, uniformity is good of the products drying.

In the meantime of drying can also achieve the purpose of sterilization and deodorization.

Characteristics of NPK Fertilizer Production Line

Energy saving and consumption reducing, no waste removal, stable operation, reliable running, convenient maintenance. The adaptability of raw materials is wide, and the machine is suitable for the granulation of compound fertilizer, medicine, chemical industry, feed, etc., and the granulation rate is high. This machine can produce various compound fertilizer with different concentration and different types (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.).

Product detail pictures:

Related Product Guide:

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for 2022 New Style Raw Materials For Organic Fertilizer - Roller press granulator production line – Tianci , The product will supply to all over the world, such as: Naples, Madagascar, Indonesia, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178