Product

Full granulation function and high production efficiency

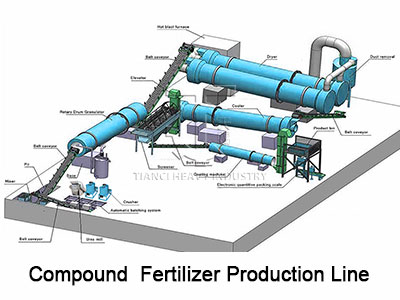

Bulk Blending Fertilizer Production Line

Introduction of Bulk Blending Fertilizer Production Line

The full name of BB fertilizer is bulk blending fertilizer. It is a kind of compound granule fertilizer mixer for several single fertilizers or compound fertilizers according to certain proportion. It has characters of granule uniformity, less water, granule intensity moderate, no agglomeration store, easy to use and low cost. BB fertilizer production line usually includes 3 processes, batching, mixing and packaging.

Working Process

Equipments of bulk blending compound fertilizer production line:

| 1 | Batching System | to reduce work intensity, increase output, achieve continuous production, and improve formula accuracy. |

| 2 | Mixing Machine | mixing and stirring NPK fertilizer granules. |

| 3 | Package Machine | Packing fertilizer granules into bags, which can improve work efficiency and reduce operating costs. |

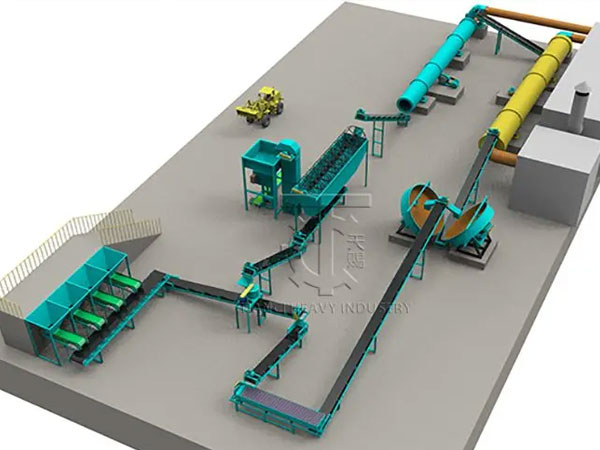

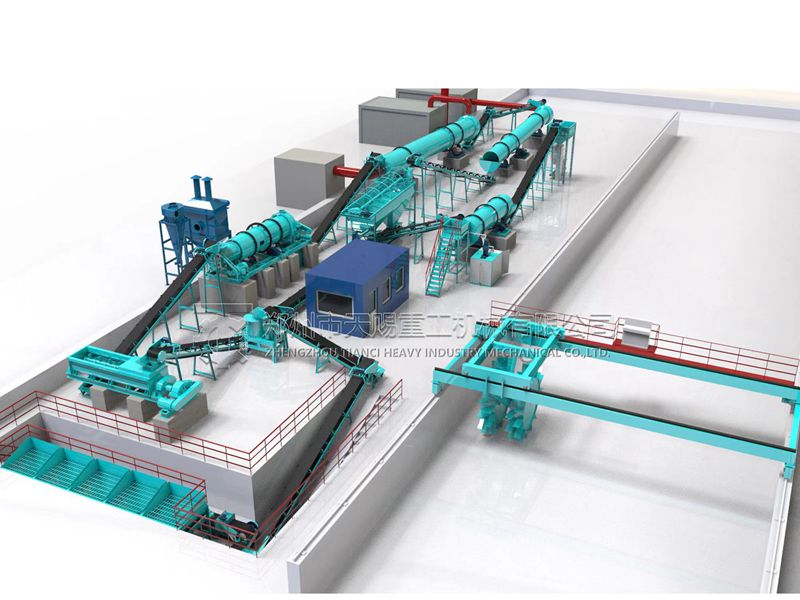

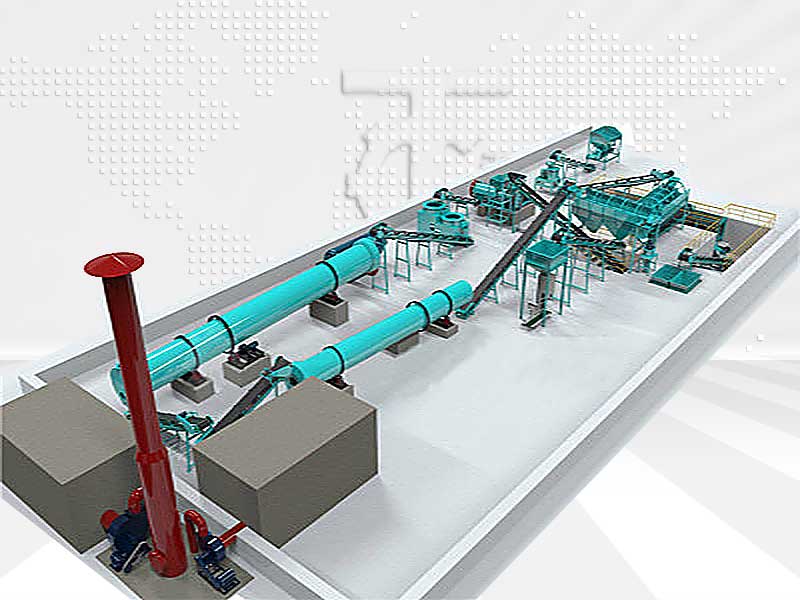

Working Project

Bulk blending compound fertilizer production line from our old customers:

The Features of Bulk Blending Fertilizer Production Line

Delivery

Package : wooden package or full 20GP/40HQ container

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8618937171932

+8618937171932