Product

Full granulation function and high production efficiency

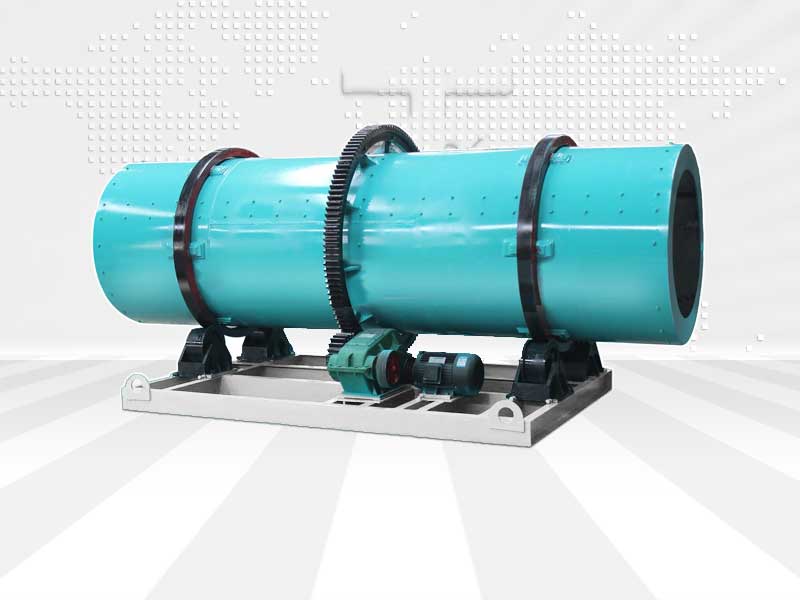

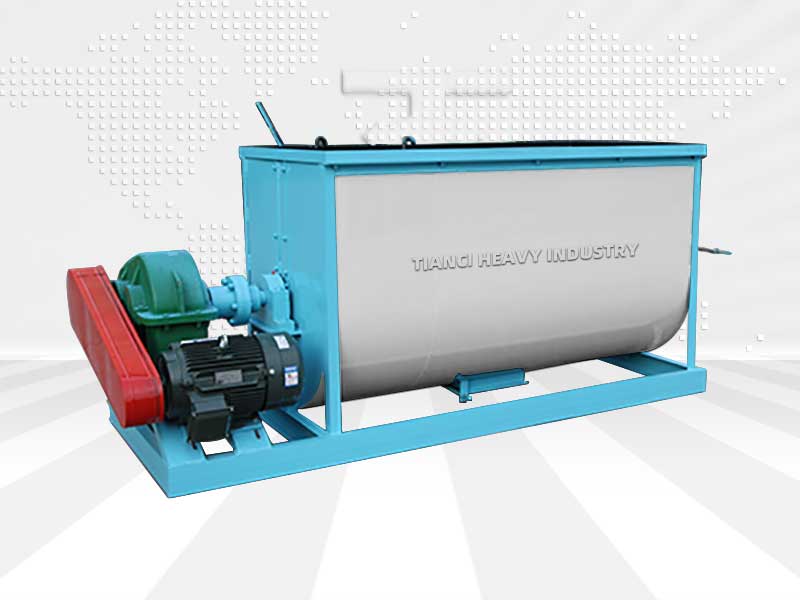

Best Price for Rotary Drum Fertilizer Granulator - NPK and Compound Fertilizer Granulator – Tianci

Best Price for Rotary Drum Fertilizer Granulator - NPK and Compound Fertilizer Granulator – Tianci Detail:

Product Description

This fertilizer granulator is a new type of granulator for organic fertilizer after many improvements on the basis of the traditional granulator for roller extrusion.It has advanced technology, reasonable design, compact structure, novel and practical, low energy consumption. It can form a small production line with the corresponding equipment. It can form a certain capacity of continuous and mechanized production. Adopting healthy formula, no need for drying, normal temperature production, product rolling forming, make product quality meet the technical requirements of compound fertilizer, is used for the production of various crops high, medium and low concentration of special compound fertilizer and compound fertilizer industry energy saving and consumption reduction replacement products.

Performance Characteristics

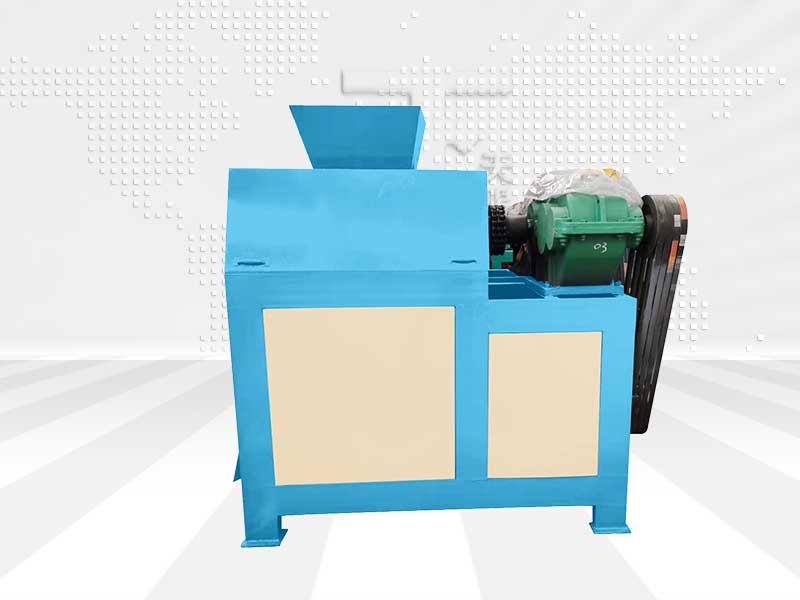

1.The kinetic energy transfer is increased to five slots triangle belt, which fully transfers the motor power and reduces the kinetic energy loss.

2.The reducer adopts the independent research and development design of our company, with high transmission efficiency and stable kinetic energy.

3.Design the feeding and stirring mechanism to ensure that the material can enter the roller die evenly and prevent the feeding mouth from blocking.

4.Both sides of the lower end of the roller skin mold are equipped with automatic cleaning scraper to prevent materials from sticking to the roller skin.

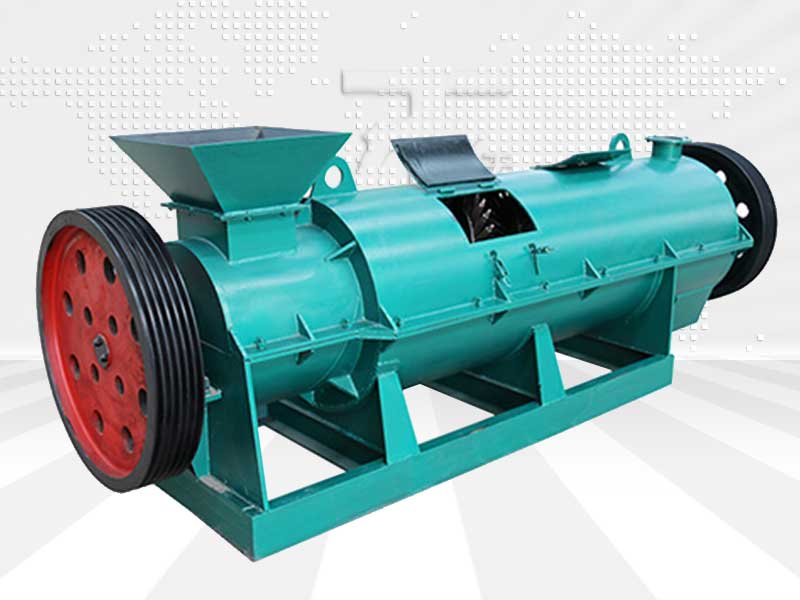

Working Principle

This series of roller granulation belongs to extrusion sliding model, whose working principle is: the belt and belt pulley are driven by an electric motor, and transmitted to the drive shaft by reducer, and work in the same direction through the open gear and the passive shaft.The material is added from the feed hopper, extruded by the roller, demoded and pelleted, and passed through a pair of chains to the crushing screen studio, where the finished product pellets (balls) are screened and separated, and then the material is returned and mixed with new materials for granulation.With the continuous rotation of the motor and the continuous entry of materials, mass production can be realized.

Main Technical Parameters

|

Model |

DZJ-Ⅰ-1.0 |

DZJ-Ⅰ-2.0 |

DZJ-Ⅰ-3.0 |

DZJ-Ⅰ-4.0 |

DZJ-II-1.0 |

DZJ-II-2.0 |

DZJ-II-3.0 |

|

Production capacity (t/h) |

1-1.5 |

1.5-2.5 |

2.5-3.5 |

3.5-4.5 |

1-2 |

1.5-2.5 |

2.5-3.5 |

|

Power |

15kw |

18.5kw |

22kw |

45kw |

15kw |

18.5kw |

22kw |

|

Pressure roller size |

Φ150×220 |

Φ150×300 |

Φ186×300 |

Φ300×300 |

Φ150×220 |

Φ150×300 |

Φ186×300 |

|

Feeding size |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

≤0.5mm |

|

Finished product specifications |

Φ2.5-φ10 |

Φ2.5-φ10 |

Φ2.5-φ20 |

Φ2.5-φ30 |

Φ2.5-φ10 |

Φ2.5-φ20 |

Φ2.5-φ20 |

|

Reducer type |

ZQH350 |

ZQH400 |

ZQH400 |

ZQH500 |

special-purpose |

special-purpose |

special-purpose |

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for Best Price for Rotary Drum Fertilizer Granulator - NPK and Compound Fertilizer Granulator – Tianci , The product will supply to all over the world, such as: Honduras, San Francisco, Uruguay, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178