Product

Full granulation function and high production efficiency

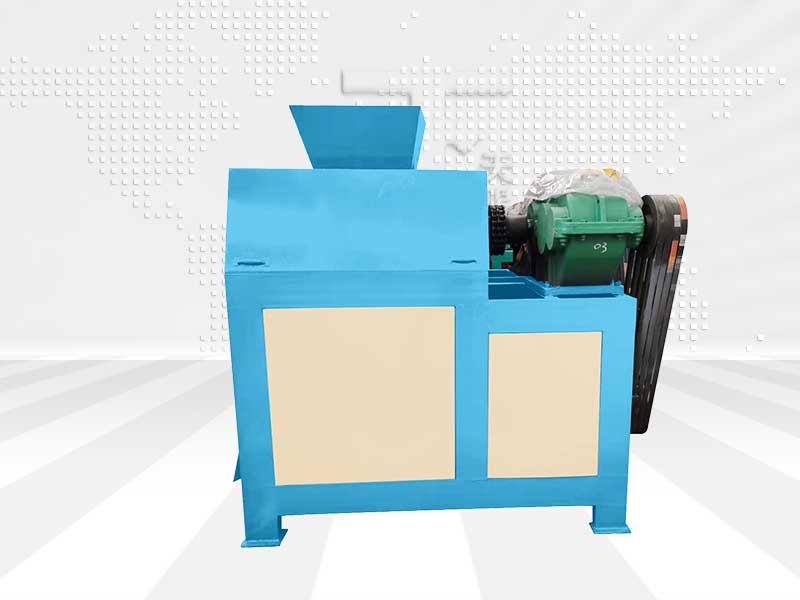

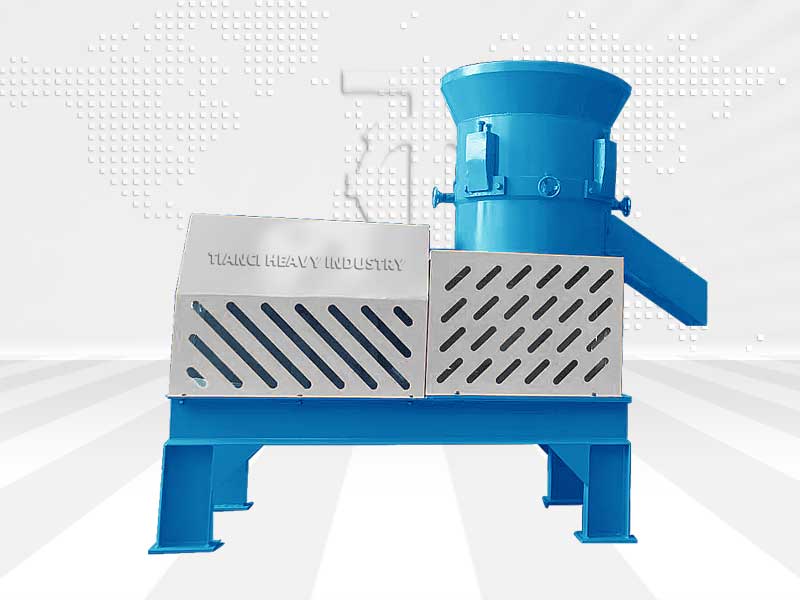

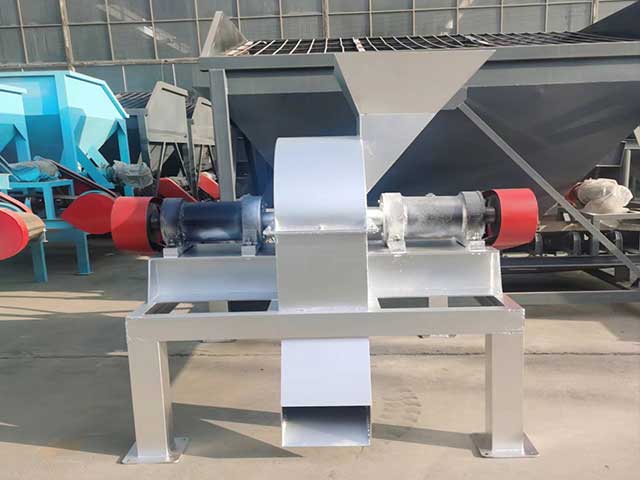

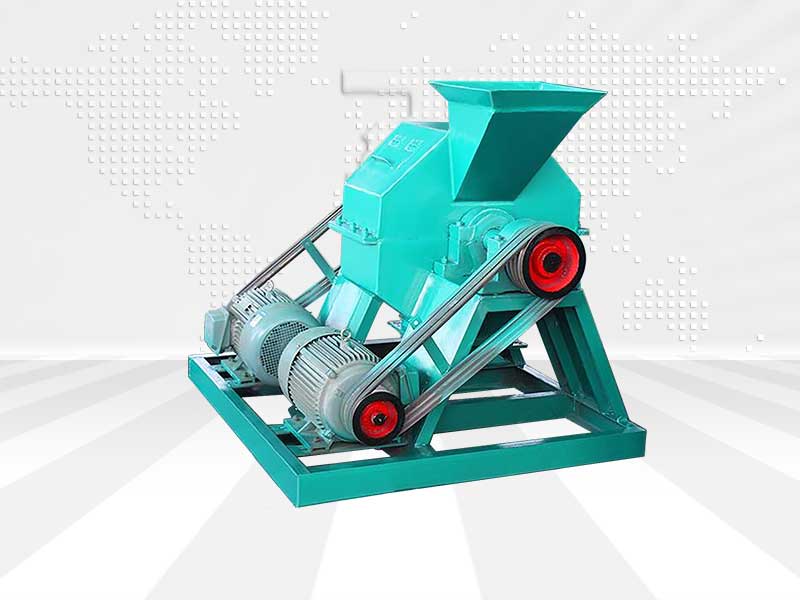

China wholesale Chain Crusher - Cage Crusher-Crushed urea / monoammonium – Tianci

China wholesale Chain Crusher - Cage Crusher-Crushed urea / monoammonium – Tianci Detail:

Product Description

Cage crusher is medium-sized horizontal cage bars crusher. The machine is designed according to the principle of impact breaking. The inside and outside two sets of cage bars rotates in opposite direction with high speed, then the material is crushed by the impact of the cage bar when through the two sets of cages, which is the ideal tool for compound fertilizer crushing.

Features

The cage of the cage crusher is composed of two cages, large and small. The two cages operate in reverse and have strong impact. The small cage is sleeved with the large cage. After being impacted and crushed by the small cage rod, the material is violently impacted by the reverse large cage rod, and then it is impacted and crushed again by the high-speed phase throwing shell. The material has been completely crushed into powder.

One end of the main shaft is connected to a pulley, and the other end is a fixed cage. The middle is fixed by two bearings with a certain distance, and the structure is firm.

the cage bar is processed with key strips, with increased density, and is evenly fixed between two thick steel plates. Adjust the dynamic and static balance to ensure stable operation.

Due to the high running speed of the cage crusher, the crushed materials are powder, and the strong air flow blows the powder materials out of the shell, which is very easy to produce dust. Therefore, our company produces a dust collector to achieve the effect of dust removal and material recovery. Environmental protection and energy conservation.

Cage powder is placed and fixed on the conical silo. Most of the materials are impacted by the high-speed air flow to the wall of the conical silo and deposited. A small part of the materials are discharged from the silo in the form of dust with the air flow, and are pumped into the dust collector by the fan on the spiral dust collector. After spiral dust removal, there is no dust, so they can be directly discharged into the atmosphere or discharged into the atmosphere after dedusting in the pool.

The thick rubber pad is attached between the cage powder and the connecting piece of the silo to achieve the shock absorption effect.

The silo and dust removal have been equipped with a fixed frame, which has been matched with the cage powder, and the screws can be directly connected during installation.

Working Principle

The transmission mode of cage crusher is divided into bilateral motor transmission. The cylinder is welded on the frame welded by channel steel, and the rotor is inside the cylinder. The main shafts are respectively seated on both sides of the cylinder and connected with the motor through belts. The feeding port is opened on one side of the cylinder, and the discharging port is under the shelf. The whole crusher is supported by four legs. During the production and operation of the crusher, the motor drives two concentric spindles to rotate in the opposite direction. The materials enter the inner cage from the feed inlet, and then enter the outer cage after crushing. The materials are constantly knocked back and forth by the steel bars on the cage between the two rotating cages, so that the material powder is more crushed and the effect is better.

Main Technical Parameters

|

Model |

Rotate speed (r/min) |

Power (kw) |

Prod Capacity (t/h) |

Overall Dimensions L×W×H(mm) |

|

WLF650 |

2000 |

26 |

4-6 |

1800×1300×1160 |

|

WLF800 |

2000 |

37 |

6-10 |

2200×1500×1360 |

Product detail pictures:

Related Product Guide:

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for China wholesale Chain Crusher - Cage Crusher-Crushed urea / monoammonium – Tianci , The product will supply to all over the world, such as: Australia, Birmingham, Provence, Our main objectives are to provide our customers worldwide with good quality, competitive price, satisfied delivery and excellent services. Customer satisfaction is our main goal. We welcome you to visit our showroom and office. We are looking forward to establish business relation with you.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178