Product

Full granulation function and high production efficiency

Discount wholesale Cow Dung Drum Granulator - Disc Granulator-Production of fertilizer particles and ore clay particles – Tianci

Discount wholesale Cow Dung Drum Granulator - Disc Granulator-Production of fertilizer particles and ore clay particles – Tianci Detail:

Applications and Features

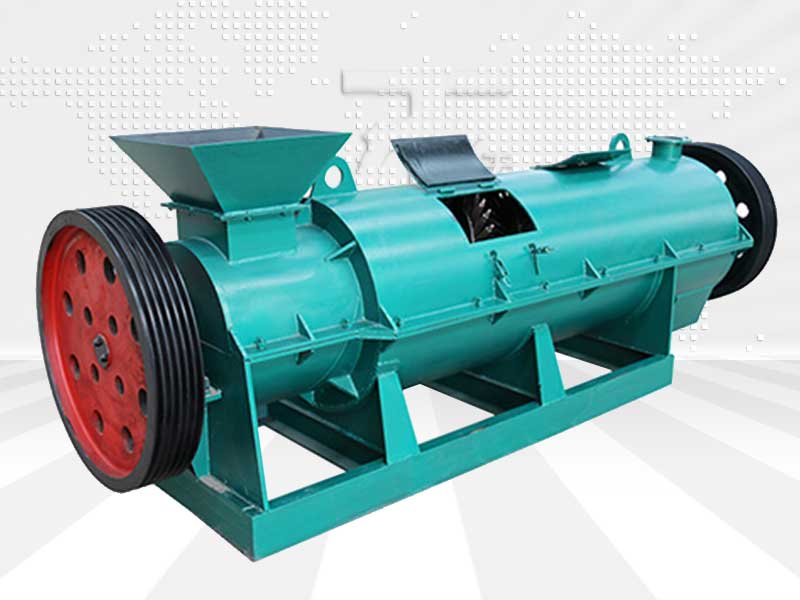

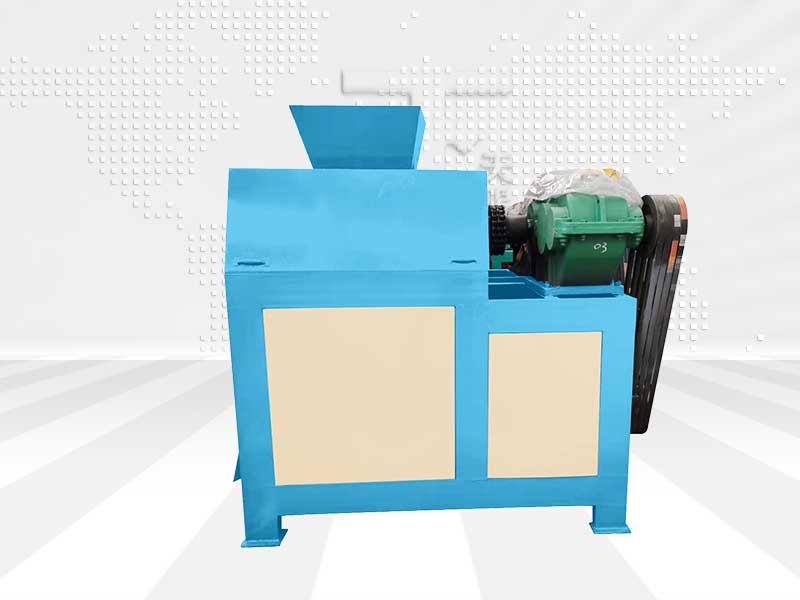

Frame part: As the whole body part of the transmission and the rotating part of the work supporting by rack, with strength force, so the machine frame parts are welding with excellent carbon channel, and adopted a rigorous quality certification and specific Of the technical requirements, has reached the purpose of the machine used.

Adjustment part: the most important part of whole machine is granulation disk, and the gravity center of granulation disk is installed on adjust part, our company specializes in the use of excellent welding carbon steel plate and channel steel, and adopted a strict quality standards Certification, have reached the requirements of the machine used.

Transmission parts: the entire machine drive part is important, the overall work depend on it. The motor installed on transmission rack and reducer are with ISO / 9001 quality products, with reliable quality. The motor drive Pulley, V-belt, Reducer and pinion, the small gear transmission large gear and drive the granulation plate work. The gears are used high-frequency fire, with twice service life than old type. The granulation plate is fixed on the driving shaft , the connecting part of the stigma adopts the taper fitting, the design is more reasonable;

Granulation part: This machine granulator disk angle with the overall arc design, granulation rate can reach more than 90%, granulation disk bottom also uses a number of radiation steel to strengthen, durable, never deformation;

Automatic cleaning part: This part is installed on the top of the granulator, into frame shape, with automatic clear plate, in order to clear the material attached to the machine when production, highly improving the service life of the machine, Saving the labor force.

The series of disc granulator has a variety of models, according to the user’s different capacity, also accept custom.

Main Technical Parameters

|

Model |

Inner diameter (mm) |

Side height (mm) |

Volume (m³) |

Rotation speed (r/min) |

Motor power(KW) |

Prod capacity (T/h) |

Decele rators model |

|

ZL10 |

1000 |

250 |

0.4 |

24 |

2.2 |

0.3-0.5 |

XW5-59 |

|

ZL15 |

1500 |

300 |

1.1 |

22 |

5.5 |

0.5-0.8 |

ZQ250-48 |

|

ZL18 |

1800 |

300 |

1.4 |

18 |

5.5 |

0.6-1.0 |

ZQ250-48 |

|

ZL20 |

2000 |

350 |

1.8 |

18 |

7.5 |

0.8-1.2 |

ZQ250-48 |

|

ZL25 |

2500 |

350 |

2.5 |

18 |

7.5 |

1.0-1.5 |

ZQ400-23 |

|

ZL28 |

2800 |

400 |

3.3 |

18 |

11 |

1.0-2.5 |

ZQ400-48 |

|

ZL30 |

3000 |

450 |

3.9 |

16 |

11 |

2.0-3.0 |

ZQ350-23 |

|

ZL32 |

3200 |

500 |

4.3 |

13.6 |

15 |

2.0-3.5 |

ZQ350-23 |

|

ZL36 |

3600 |

550 |

5.5 |

11.3 |

18.5 |

3.0-5.0 |

ZQ400-23 |

|

ZL45 |

4500 |

600 |

6.5 |

8 |

22 |

4.0-6.0 |

ZQ250-48 |

Product detail pictures:

Related Product Guide:

It can be our duty to satisfy your preferences and successfully serve you. Your pleasure is our best reward. We have been looking forward to the go to for joint expansion for Discount wholesale Cow Dung Drum Granulator - Disc Granulator-Production of fertilizer particles and ore clay particles – Tianci , The product will supply to all over the world, such as: Greece, Cologne, UK, Due to our good products and services, we have received good reputation and credibility from local and international customers. If you need more information and are interested in any of our products, please feel free to contact us. We look forward to becoming your supplier in the near future.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178