Product

Full granulation function and high production efficiency

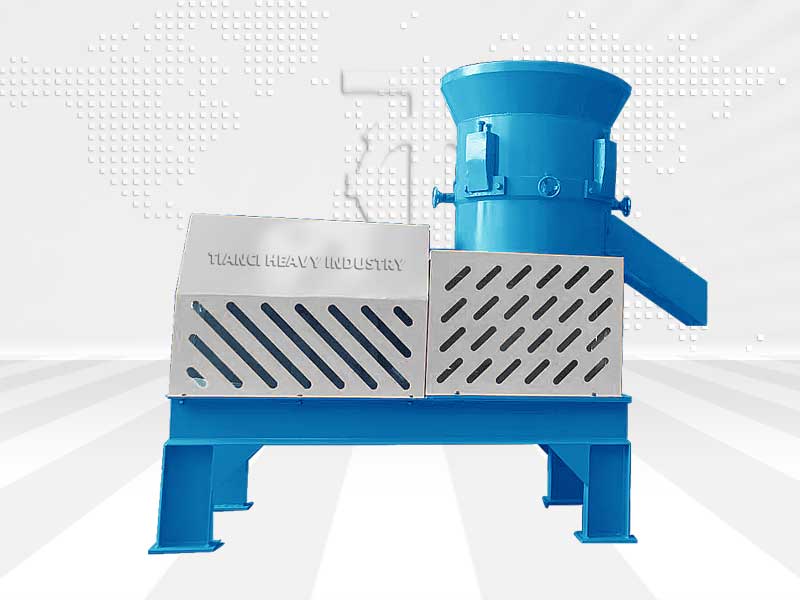

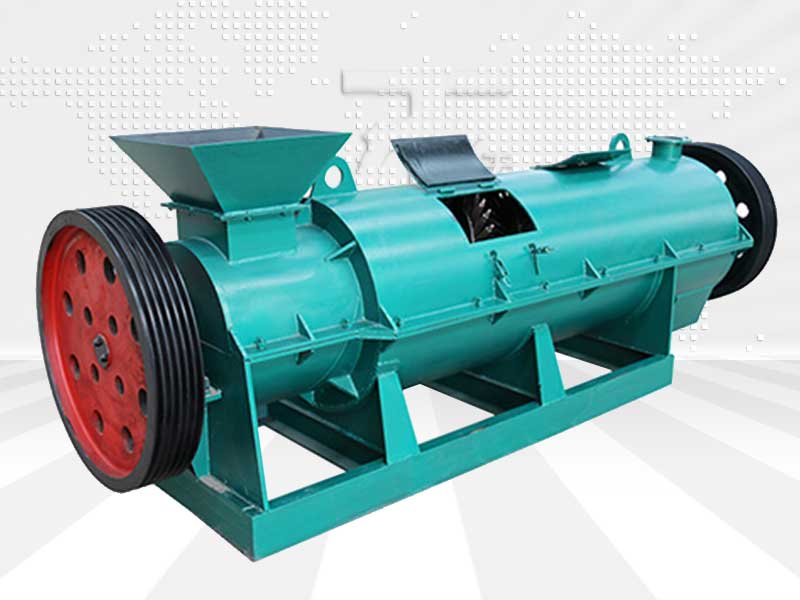

Factory Cheap Hot Npk Manufacturing Process - Coating machine-Roller type fertilizer coating machine – Tianci

Factory Cheap Hot Npk Manufacturing Process - Coating machine-Roller type fertilizer coating machine – Tianci Detail:

Working Principle

The working principle of this series of rotary coating machines is as follows: the main motor drives the belt and pulley, which is transmitted to the driving shaft through the reducer, and the split gears installed on the driving shaft and the large ring gear fixed on the body are in phase with each other. Work together. The material is added from the feed end and passes through the inside of the cylinder. Under the suction of the induced draft fan (used with this machine), the air flow inside the cylinder is accelerated.

Structure Overview

1. Bracket part: The entire rotating part of the body is supported by the bracket, and the force is large. Therefore, the supporting parts of the machine are all welded with medium carbon steel plates and channel steel, and have passed strict quality control and special process requirements, and have achieved the purpose of this machine. In addition to this, the more important thing is the supporting roller fixed on the shelf. Considering that it will have greater friction with the rolling belt of the body, our factory specially selects high-quality anti-corrosion and wear-resistant materials, which greatly improves the service life of the machine. The frame also adopts casting integrated technology. In addition, there are hoisting hooks at the four corners of the supporting wheel frame, which is convenient for loading, unloading and transportation.

2. Transmission part: The transmission part is particularly important, and the work of the whole machine is based on this. The transmission frame is welded with high-quality channel steel and has passed strict quality requirements. The main motor and reducer installed on the transmission frame are selected from ISO national inspection-free products, and the quality is reliable. The motor drives the pulley, the V-belt and the reducer to transmit to the main shaft to make the body work. The transmission reducer and the working part of the main shaft are driven by a nylon pin coupling.

3. Large ring gear: It is fixed on the machine body and meshes with the transmission pinion to drive the machine body to work in the opposite direction. It adopts high-tech wear-resistant materials to make the machine last longer.

4. Rolling belt: fixed on both sides of the body to support the whole body.

5. Body part: The most important part of the whole coating machine is the body part, which is welded with high-quality medium carbon steel plates, and passes strict quality control and specific process requirements to achieve the purpose of this machine.

Technical Parameters

|

Specification |

Cylinder |

Production capacity |

power |

|||

|

Diameter |

Length |

inclination |

Rotary speed |

|||

|

mm |

mm |

mm |

(°) |

r/min |

t/h |

kw |

|

BM1200×4000 |

1200 |

4000 |

3 |

14 |

~5 |

5.5 |

|

BM1400×4000 |

1400 |

4000 |

13 |

~7 |

7.5 |

|

|

BM1600×6000 |

1600 |

6000 |

12 |

~15 |

11 |

|

|

BM1800×8000 |

1800 |

8000 |

12 |

~30 |

15 |

|

Product detail pictures:

Related Product Guide:

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for Factory Cheap Hot Npk Manufacturing Process - Coating machine-Roller type fertilizer coating machine – Tianci , The product will supply to all over the world, such as: Australia, Egypt, Philadelphia, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178