Product

Full granulation function and high production efficiency

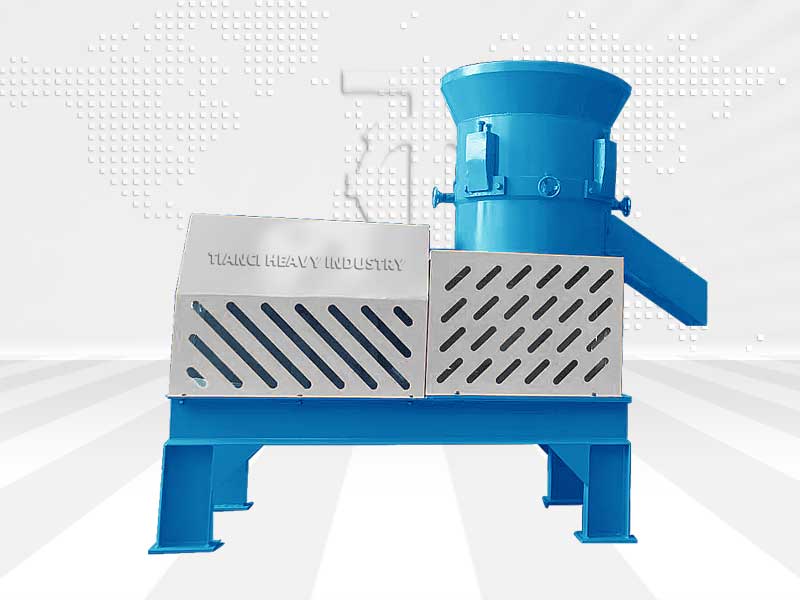

Factory wholesale Fertilizer Making Machine - Cost Efficient Powdery Organic Fertilizer Production Line – Tianci

Factory wholesale Fertilizer Making Machine - Cost Efficient Powdery Organic Fertilizer Production Line – Tianci Detail:

Suitable Raw Materials

According to local conditions, you can choose suitable raw materials.

(1) Manure: chicken manure, pig manure, cow dung, sheep manure, horse manure, rabbit manure, quail manure, pigeon dung and other animal manure;

(2) Straw: corn straw, corncob, straw, wheat straw, bean straw, sweet potato straw, grain stalk, etc.;

(3) Cakes: bean cake, soybean meal, oil cake, rapeseed cake, peanut cake, sesame cake, etc.;

(4) Sludge: domestic sludge, sugar mill filter, paper sludge, etc.;

(5) Adding raw materials: plant growth regulators, synergists, anti-caking agents, colorants, brighteners, binders, medium and trace elements, a large number of elements, carrier materials.

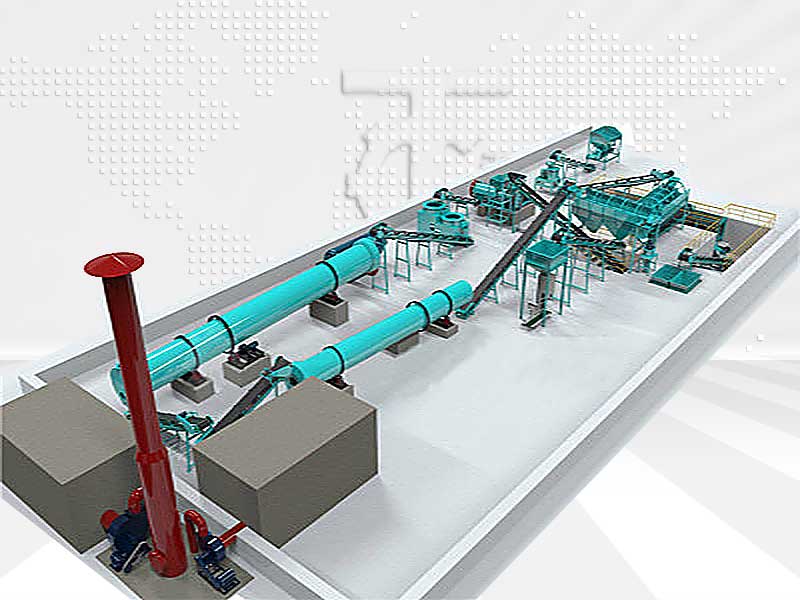

Process Flow

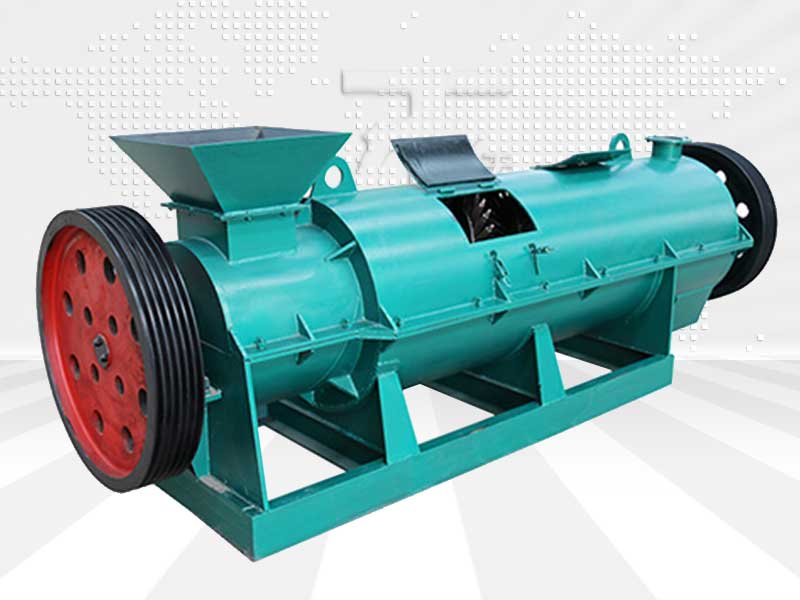

Raw material & auxiliary materials → material mixing → first fermentation → crushing → screening →measurement packing

The small powder organic fertilizer production line equipment is very suitable for the manure processing of small farms. It not only solves the environmental problems of manure but also increases the income of the farms. The whole organic fertilizer production line only needs 2-3 people to operate. If the surrounding raw materials are sufficient to expand production, please come to our factory to discuss the appropriate complete set of equipment process according to the output.

Characteristics of powdery organic fertilizer production line: it features simple installation, low investment, quick response, easy operation and economic & environmental protection.

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for Factory wholesale Fertilizer Making Machine - Cost Efficient Powdery Organic Fertilizer Production Line – Tianci , The product will supply to all over the world, such as: Armenia, Jamaica, Danish, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178