Product

Full granulation function and high production efficiency

Good Quality Chicken Manure Dryer Machine - Drum Fertilizer Dryer – Tianci

Good Quality Chicken Manure Dryer Machine - Drum Fertilizer Dryer – Tianci Detail:

Product Introduction

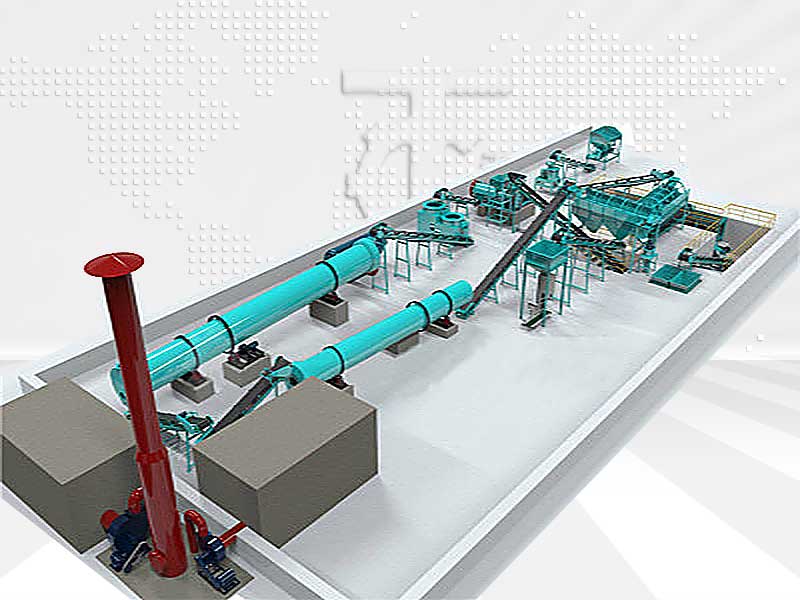

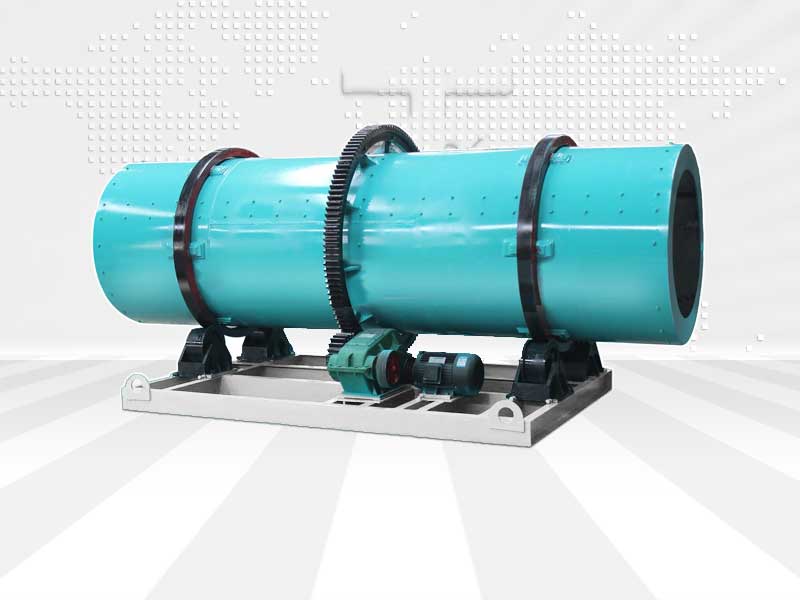

Rotary drum fertilizer dryer is mainly used for drying granular organic fertilizer and granular compound fertilizer. In view of the characteristics that the water content of organic fertilizer particles or compound fertilizer / compound fertilizer particles is not more than 35%, and the hardness of fertilizer particles is smaller than that of coal slime, the lifting plate and barrel of this dryer are optimized to avoid destroying the shape of fertilizer particles.

Performance Characteristics

High efficiency in heatin

The distribution and angle of the lifting plate of the rotary dryer are reasonable and the performance is reliable, so the heat energy utilization rate is high and the drying is uniform.

Lower energy consumption

The rotary dryer has a large processing capacity, low fuel consumption, and low drying cost.

Reduces wear

The rotary dryer equipment adopts a self-aligning tug structure, and the tug and the rolling ring cooperate well, which greatly reduces wear and power consumption.

Protecting the shape of fertilizer particles

As the fertilizer particles are relatively fluffy and the hardness is not high, the lifting plate and the cylinder have been specially treated at the rotating speed, so as to reduce the damage of the dryer to the fertilizer particles and achieve the purpose of protecting the particle shape.

Working Principle

Rotary drum fertilizer dryer is mainly used for drying granular organic fertilizer and granular compound fertilizer. The fertilizer particles are transported to the feed port of the fertilizer dryer through the conveyor. The fertilizer particles enter from the feed port of the dryer, and the drying heat source is introduced into the heat source through the induced draft fan from the lower port. Thus, the material falls from the feed port and flows from the bottom to the top with the hot air to form the reverse contact between the fertilizer and the heat source, and then moves to the discharge port of the dryer at different speeds. Under the action of the lifting plate, the fertilizer particles keep lifting and then fall, so that the fertilizer and the heat source are fully contacted, Realize rapid evaporation of water to meet the requirements of target water content.

Drum Fertilizer Dryer-parameters

| Model | Diameter (mm) | Length (mm) | Dip Angle (°) | Speed (r/min) | Throughput (t/h) | power (kw) |

| ZG12×6 | 1200 | 6000 | 3 | 5 | 0.5-1 | 5.5 |

| ZG14×7 | 1400 | 7000 | 3 | 5 | 2-3 | 7.5 |

| ZG16×8 | 1600 | 8000 | 3 | 5 | 3-5 | 11 |

| ZG18×9 | 1800 | 9000 | 3 | 4 | 4-6 | 15 |

| ZG20×10 | 2000 | 10000 | 3 | 4 | 6-8 | 18.5 |

Product detail pictures:

Related Product Guide:

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for Good Quality Chicken Manure Dryer Machine - Drum Fertilizer Dryer – Tianci , The product will supply to all over the world, such as: Korea, UK, Armenia, With the first-class products, excellent service, fast delivery and the best price, we have won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

Get quotation

Get quotation +8613203835178

+8613203835178