Product

Full granulation function and high production efficiency

High Quality Fertilizer Crusher Machine - Vertical Crusher – Tianci

High Quality Fertilizer Crusher Machine - Vertical Crusher – Tianci Detail:

Applications and Features

Brief introduction

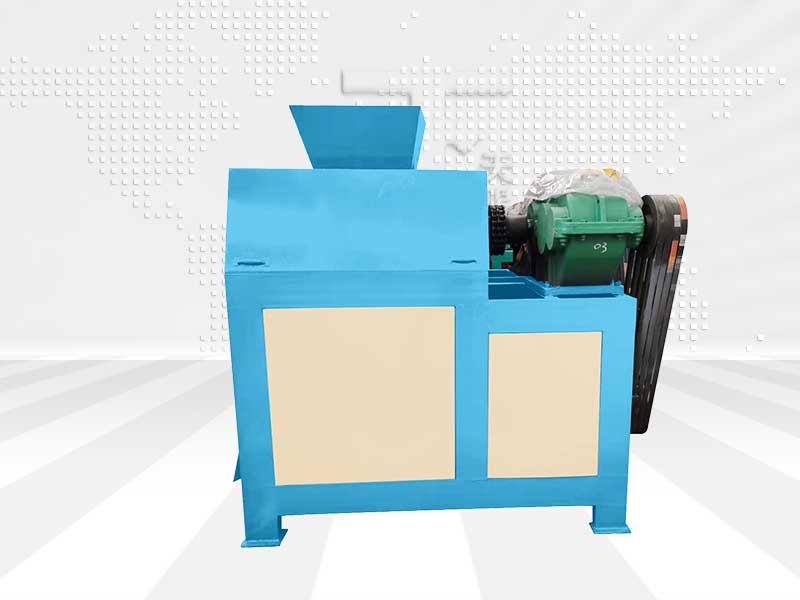

The series of semi-wet material crusher is a professional one with many years experience and advanced crushing technology at home and abroad by our scientific research personnel. The machine completely solve the problem of organics crushing with high moisture content, which is a national initiative, and declare the national patent. The successful development of this machine played a key role in cutting down the process of the bio-organic and compost fertilizer, Reduce equipment investment and Saving running cost.

Application and features

The moisture content demand for Biological fermentation organic fertilizer is between 25-50% with this machine, and Crushing size meets the requirements of granulation. it also played an effect of grinding for glass, ceramics, bricks and gravel from organic fertilizer made of City life garbage, and reached the result for safe application. It is an ideal machine for fertilizer production and processing organization.

Brief Introduction Of Structure

The machine can be divided into three parts:

1. Machine body: All the normal operation of the machinery are inseparable from the solid frame, which adopt excellent carbon steel plate by Channel steel welded together, and passed a rigorous product certification and specific process requirements, in order to achieve the goal of normal operation.

2.rotor part: It’s rotor adopted new structure and reasonable design, which uses the upper and lower double layer blade crushing, and the crushing effect is twice as high as other products. The material enters the crushing chamber from the feeding mouth, with a continuous grinding of the double blade, makes the material meet the granulation requirement.

3.driving joint part: The machine uses a flexible belt drive. The pulley and belt are driven directly by motor to the spindle, and through the high-speed rotation of spindle to achieve crushing effect.

Main Technical Parameters

|

Model |

BSFS-40 |

BSFS-60 |

BSFS-90 |

BSFS-110 |

|

Yield (t/h) |

1-2 |

2-4 |

4-8 |

10-15 |

|

Particle size |

0.5-5 |

0.5-5 |

0.5-5 |

0.5-5 |

|

Power |

22 |

30 |

37 |

45 |

|

Overall Dimensions L×W×H |

960×560 ×850 |

1632×1560 ×1180 |

2120×2040 ×1800 |

2160×2276 ×1880 |

Product detail pictures:

Related Product Guide:

Our staff through skilled training. Skilled skilled knowledge, potent sense of company, to satisfy the provider requirements of consumers for High Quality Fertilizer Crusher Machine - Vertical Crusher – Tianci , The product will supply to all over the world, such as: Muscat, Switzerland, St. Petersburg, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178