Product

Full granulation function and high production efficiency

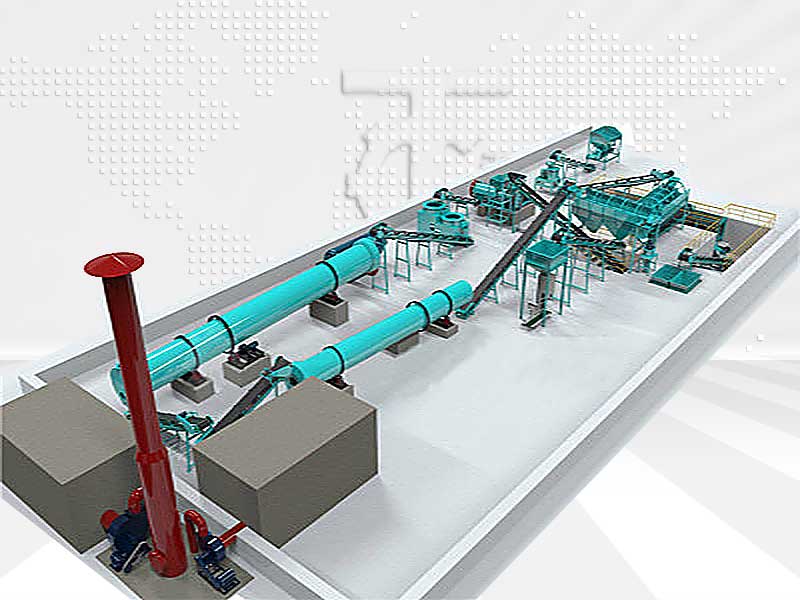

Manufacturer for Drum Dryer Machine - Cooling Rotary Drum Cooler Machine – Tianci

Manufacturer for Drum Dryer Machine - Cooling Rotary Drum Cooler Machine – Tianci Detail:

Product Introduction

Rotary drum cooling machine is used for cooling fertilizer with certain temperature and particle size in fertilizer industry.

Performance characteristics

Easy to operate and maintain

Rotary drum cooler simple structure, high operation rate, easy operation and maintenance.

High heat exchange efficiency

All the air cooled from material goes into the kiln for the second cycle, in order to improve the thermal efficiency of the kiln.

Improve the quality of dried products

Clinker from the rotary kiln (1000-1200℃) through the cylinder rotation to promote full heat exchange between the material and air. As a result, the material can be cold(200℃ or less) , so the quality and grindability of clinker improving.

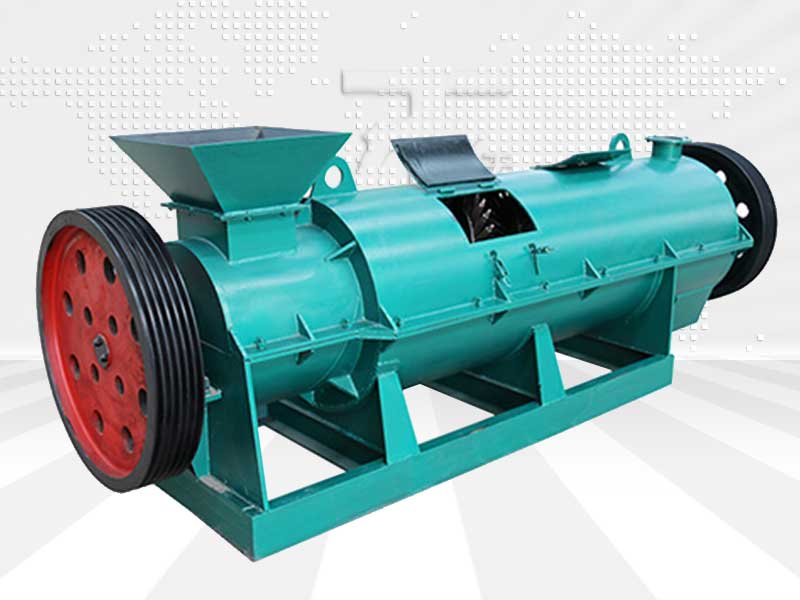

Working principle

Rotary Drum Cooler adopts heating exchange method to cool materials. It is equipped with welded steel spiral scraping wings in front of the tube, lifting board at the end of the rotary body, and auxiliary piping system in the feed end of the cooling machine. The belt and pulley are driven by the main motor and through the reducer the drive shaft is put in motion.

Technical parameters of single barrel cooler

|

Model |

Capacity(t/h) |

Speed(r/min) |

Motor |

Power(KW) |

Reducer Model |

weight(t) |

|

φ1.2×12 |

1.9-2.5 |

4.5 |

Y160L-6 |

11 |

ZQ50 |

22 |

|

φ1.5×15 |

4-6 |

4.5 |

Y200L1-6 |

18.5 |

ZQ65 |

33 |

|

φ2×20 |

7-8 |

3 |

Y225M-6 |

30 |

ZL75 |

74 |

|

φ2.2×22 |

10-11.5 |

3 |

Y225M-6 |

30 |

ZL75 |

82 |

|

φ2.5×25 |

11-15 |

3.5 |

Y280S-6 |

45 |

ZL100 |

108 |

|

φ2.8×28 |

14-17 |

3.5 |

Y280M1-6 |

55 |

ZL100 |

142 |

|

φ3×30 |

16-20 |

3.5 |

YS2-355M1-6 |

112 |

ZL115 |

156 |

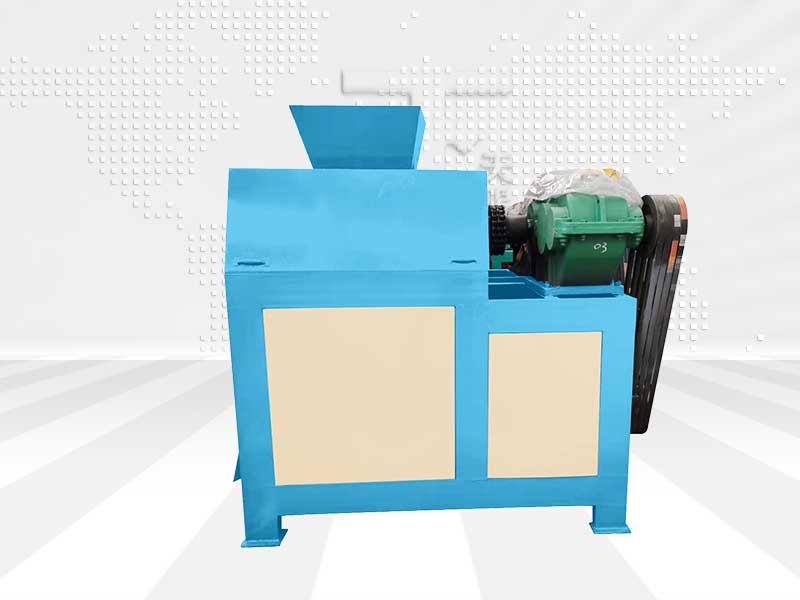

Product detail pictures:

Related Product Guide:

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Manufacturer for Drum Dryer Machine - Cooling Rotary Drum Cooler Machine – Tianci , The product will supply to all over the world, such as: Singapore, Hongkong, Munich, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178