The applications of roller extrusion granulators in the pharmaceutical, food and chemical industries are as follows:

1. Medicine: In the field of medicine, double-roller extrusion granulators are often used to make pharmaceutical raw materials into granules, such as tablets, granules, capsules, etc. The granules produced by the double-roller extrusion granulator can improve the stability and solubility of the drug, improve the taste, and make it easier for patients to take it.

2. Food: In the food field, double-roller extrusion granulators are widely used in the manufacturing of various puffed foods, candies, snacks, feeds, etc. It can produce standardized single particles, multi-particles and core particles to meet different food manufacturing needs.

3. Chemical industry: In the field of chemical industry, double-roller extrusion granulator can prepare various granular products, such as dyes, cosmetic raw materials, chemical materials, ceramic materials, fertilizers, etc. The double-roller extrusion granulator can control the size and shape of the granules, and the granules can be loose and easy to store.

In short, roller extrusion granulators are widely used in the pharmaceutical, food and chemical industries, and these industries have different requirements for granule manufacturing and equipment performance.

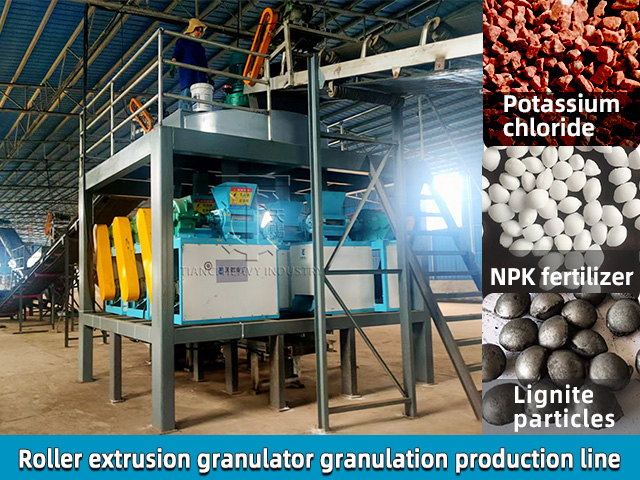

Tianci Heavy Industry’s double-roller extrusion granulator is mainly used for fertilizer extrusion and mineral powder extrusion into granules. The roller extrusion granulator is used to introduce the process and raw materials of fertilizer granules:

When the roller extrusion granulator processes chemical fertilizers, it can process regular spherical particles or irregular particles. The particle size is generally not larger than 30mm, and the common particle range is 3mm-10mm.

1. Fertilizer production line: The double-roller extrusion granulator can extrude fertilizer raw materials such as urea, ammonium chloride, ammonium dihydrogen phosphate, ammonium sulfate and other powdery or granular materials into solid particles. The granular fertilizer produced has a uniform shape and adjustable particle size, which is convenient for application and control of nutrient release speed, and improves fertilizer efficiency.

2. Organic fertilizer production line: The double-roller extrusion granulator is also suitable for organic fertilizer production lines, and can extrude and granulate organic raw materials such as livestock and poultry manure, straw, humic acid, etc. The prepared organic fertilizer particles are not only easy to store and apply, but can also improve the soil structure and increase soil nutrient content to promote crop growth.

3. Bio-fertilizer production line: Bio-fertilizer usually contains organic materials and microorganisms. The roller extrusion granulator can reasonably mix and squeeze these raw materials into granules. The prepared biological bacterial fertilizer is beneficial to the settlement and reproduction of microbial flora, improves the effect of bacterial fertilizer, and enhances the soil ecological environment.

4. Compound fertilizer production line: Compound fertilizer is a compound fertilizer that mixes a variety of fertilizer raw materials. The roller extrusion granulator can be used to granulate the compound fertilizer raw materials to ensure uniform fertilizer ingredients and improve product quality.

5. Mineral powder particle production line: extrusion of non-metallic fly ash, coal powder, carbon powder, lime powder and cement into spherical particles; extrusion of metal iron powder, magnesium, etc. into spherical particles.

To sum up, the double-roller extrusion granulator is widely used in fertilizer granule processing. It can process a variety of raw materials, and the fertilizer produced is uniform in shape and easy to apply.

Post time: Nov-24-2023