Product

Full granulation function and high production efficiency

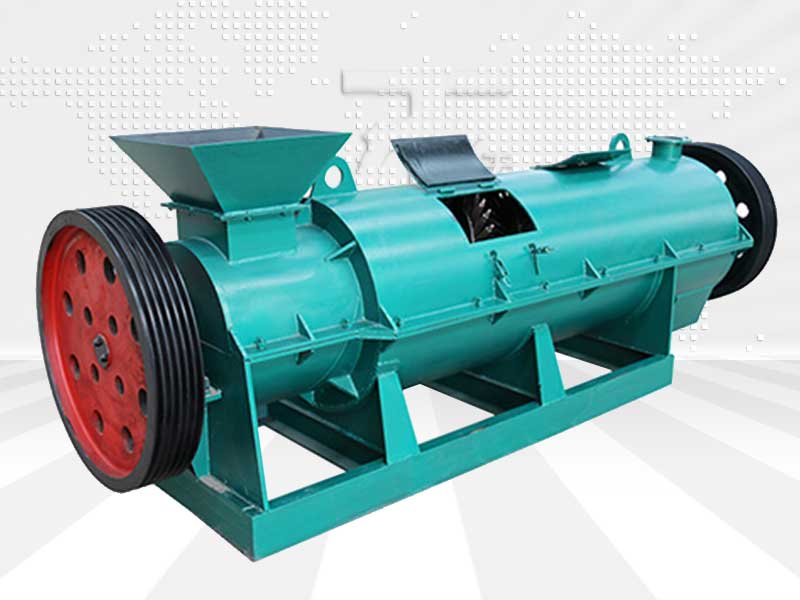

Original Factory Compound Fertilizer Hydraulic Granulator - New Type Organic Fertilizer Granulator – Tianci

Original Factory Compound Fertilizer Hydraulic Granulator - New Type Organic Fertilizer Granulator – Tianci Detail:

Product Description

The new type organic fertilizer granulator uses high speed rotating mechanical shearing force and the resulting air power, making continuous implementation of the fine powder material in the machine mixing, granulating, spheroidizing, density and other processes, which achieves the goal of the granulation. The granulation method makes the pellet rate higher, and the granule is more beautiful, while saving energy and improving efficiency.

Characteristics of Performance

The principle is simple, and the granulation speed is fast; using high speed rotating mechanical shearing force and the resulting air power makes continuous implementation of the fine powder material in the machine mixing, granulating, spheroidizing, density and other processes.

The granule quality is high and the machine is especially suitable for granulation of light powder materials. Finer particles of fine powder, higher sphericity of granules, and higher pellets quality.

No bond is required; using the particles of organic matter to be interbred with each other under certain forces, so no bond is needed for granulation.

Wide source of materials, including livestock and poultry manure, compost fertilizer, sea fertilizer, cake fertilizer, etc.

Working Principle

The new type organic fertilizer granulator uses high speed rotating mechanical shearing force and the resulting air power, making continuous implementation of the fine powder material in the machine mixing, granulating, spheroidizing, density and other processes, which achieves the goal of the granulation. The granulation method makes the pellet rate higher, and the granule is more beautiful, while saving energy and improving efficiency.

Main Technical Parameters

|

Model |

Prod Capacity |

Power (Kw) |

|

YSL-60 |

1-2t/h |

30 |

|

YSL-80 |

2-4 t/h |

45 |

|

YSL-100 |

4-6 t/h |

55 |

|

YSL-120 |

6-8 t/h |

75 |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Original Factory Compound Fertilizer Hydraulic Granulator - New Type Organic Fertilizer Granulator – Tianci , The product will supply to all over the world, such as: Provence, Germany, Mauritius, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178