Product

Full granulation function and high production efficiency

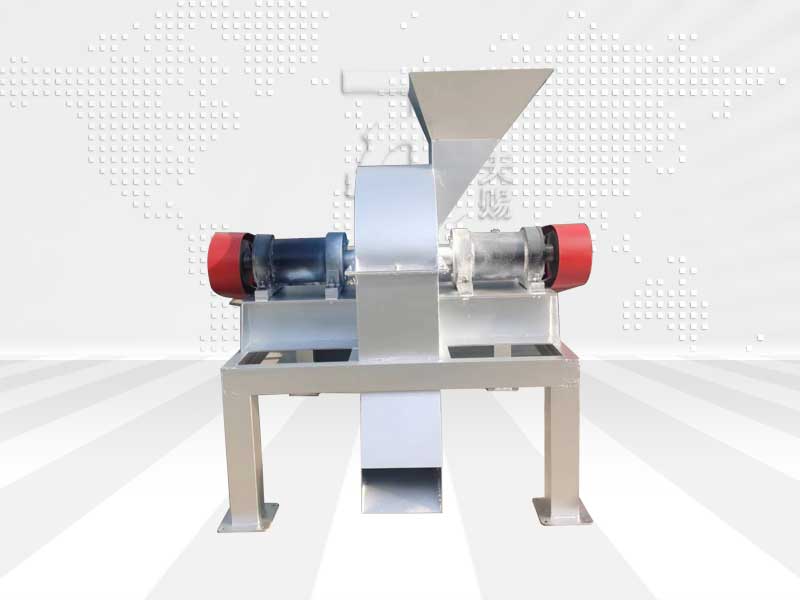

Professional China Fertilizer Crusher – Urea Crusher-Crushing particle size is less than 60 mesh – Tianci

Professional China Fertilizer Crusher – Urea Crusher-Crushing particle size is less than 60 mesh – Tianci Detail:

Product Introduction

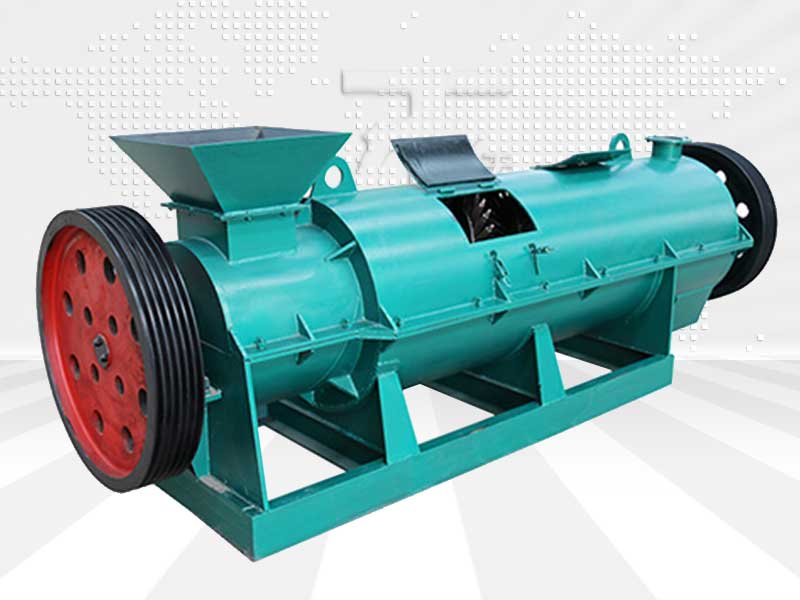

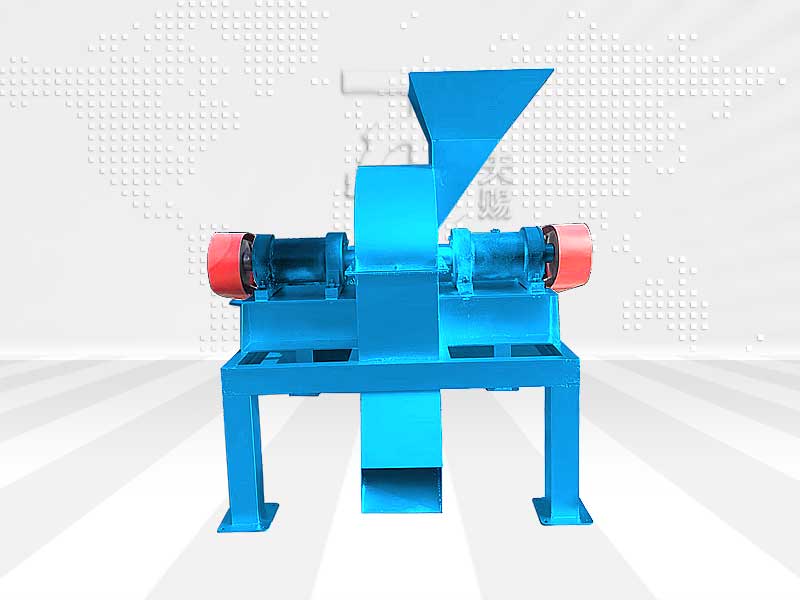

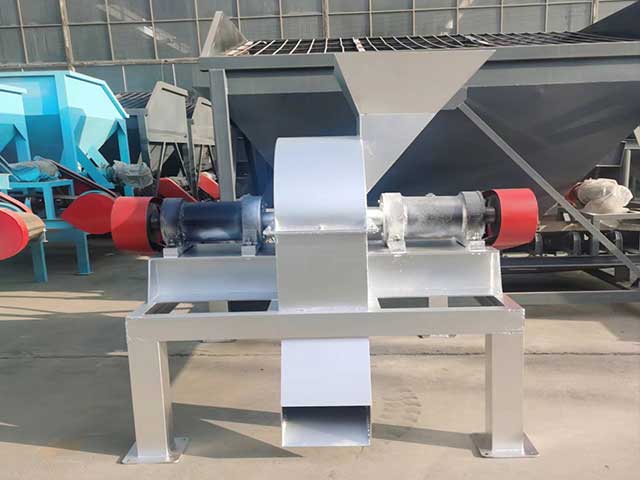

1. Urea crusher mainly uses the grinding and cutting of the gap between the roller and the concave plate.

2. The clearance size determines the degree of material crushing, and the drum speed and diameter can be adjustable.

3. When the urea enters the body, it hits the body wall and the baffle and is broken. Then it is ground into powder through the rack between the roller and the concave plate.

4. The clearance of the concave plate shall be adjustable to the extent of crushing by the regulating mechanism within 3-12 mm, and the feeding port regulator can control the production volume.

Performance Characteristics

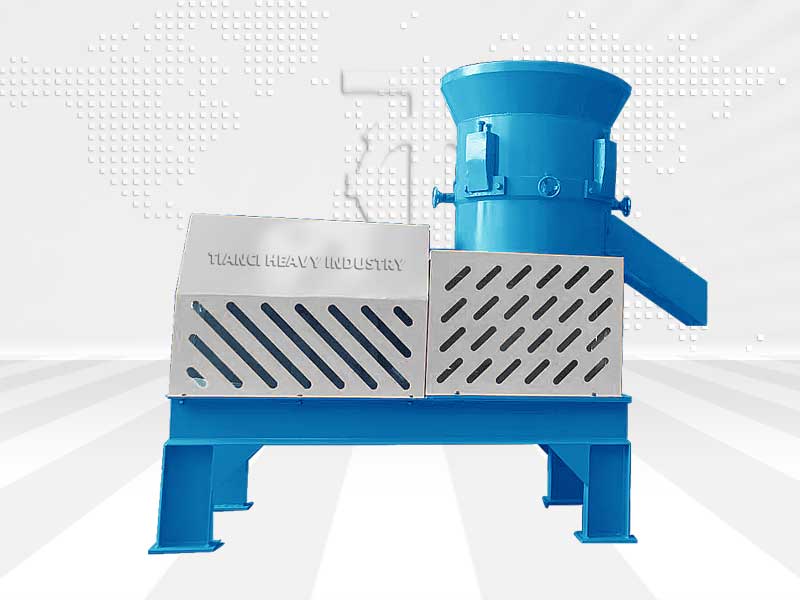

1. This machine is designed according to the principle of impact crushing, inside and outside of two groups of cage bars for high-speed rotation, material from inside out through the cage bar impact and crushing.

2. Simple structure.

3. High crushing efficiency.

4. Good sealing performance.

5. Smooth operation, easy to clean.

6. Easy to maintain and other characteristics.

Working Principle

Before use, place the shredder on a certain position in the workshop and connect it to the power source to use. The fineness of pulverization is controlled by the spacing of the two rollers. The smaller the spacing, the finer the fineness, and the relative reduction in output. The better the uniform pulverization effect is, the higher the output. The device can be designed to be mobile according to user requirements, and the user can move the corresponding position when using it, which is very convenient.

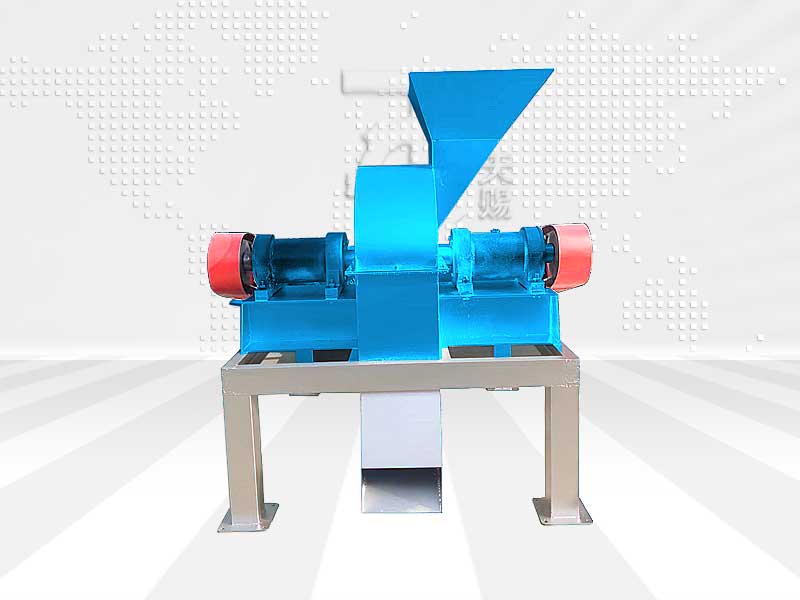

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for Professional China Fertilizer Crusher – Urea Crusher-Crushing particle size is less than 60 mesh – Tianci , The product will supply to all over the world, such as: Islamabad, Haiti, Thailand, Look forward to the future, we'll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our in depth advantages and strive for building.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178