Product

Full granulation function and high production efficiency

Professional China Fertilizer Mixing Plant - Bulk blending fertilizers mixer for specific – Tianci

Professional China Fertilizer Mixing Plant - Bulk blending fertilizers mixer for specific – Tianci Detail:

Product Description

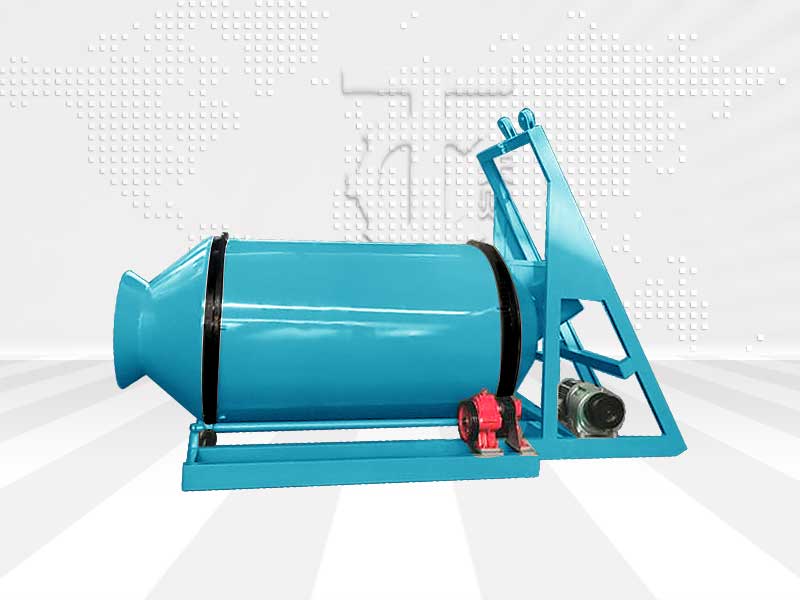

BB fertilizer mixer belongs to self-dropping touble cone reverse discharge mixer. The mixing drum rotates forward by stirring, and

discharees in reverse. Each tank can stir 350L of ferlilizer, which can produce 10-14m/h. When the mixer is fixed. the pit can be dag to

make the mouth af the hopper flush with the ground, which can greatly reduce the lahor intensity

The BB fertilizer iixer is a relatively advanced machine with some advantages, such us the novel structure, high production efficicney.

good mixing quality, light weight and attractive appearance, ete.

Product Introduction

BB fertilizer mixer overcomes the mixtures chromatography and distributaries phenomena caused by different proportion of raw materials and particle size,thus improving the accuracy of the dosing.It also solves the influence on system caused by material properties,mechanical vibration,air pressure,voltage fluctuation cold weather etc.It has the characteristics of high precision,high speed,long life,etc,which is the ideal choice in BB fertilizer (mixed) producer.

Performance characteristics

1.The mixing efficiency is high and the area is small.The spiral blade adopts high – wear special alloy.

2.Adopts reducer transmission, which is stable and has low noise.

3.It has reasonable structure. Its feeding is from the top, and the discharging is from the bottom.

4.The joint surfaces are tightly sealed and run smoothly.

Working principle

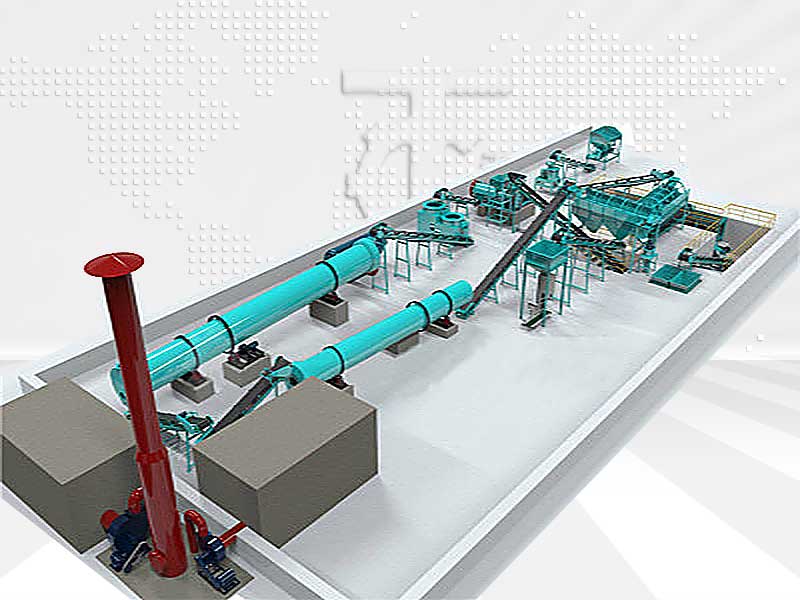

The BB fertilizer blender is input materials through the feeding lifting system, the steel bin goes up and down to feed materials, which directly discharged into the mixer, and then passed to the roller by rotation.When working, clockwise rotation mix materials, anticlockwise rotations discharge materials,the fertilizer stay in material bin for a while, then automatically drop down through the gate.This BB fertilizer machine is designed as per the requirement of the blending fertilizer plants or fertilizer distributors, and the prodution capacity can be 10–15 tons per hour.

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Professional China Fertilizer Mixing Plant - Bulk blending fertilizers mixer for specific – Tianci , The product will supply to all over the world, such as: Turkmenistan, Moldova, Jersey, We are fully aware of our customer's needs. We provide high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178