Product

Full granulation function and high production efficiency

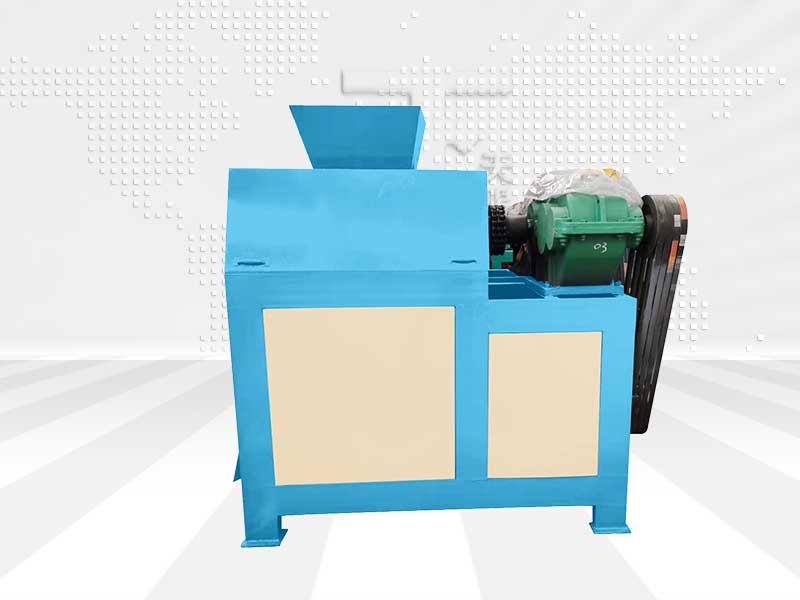

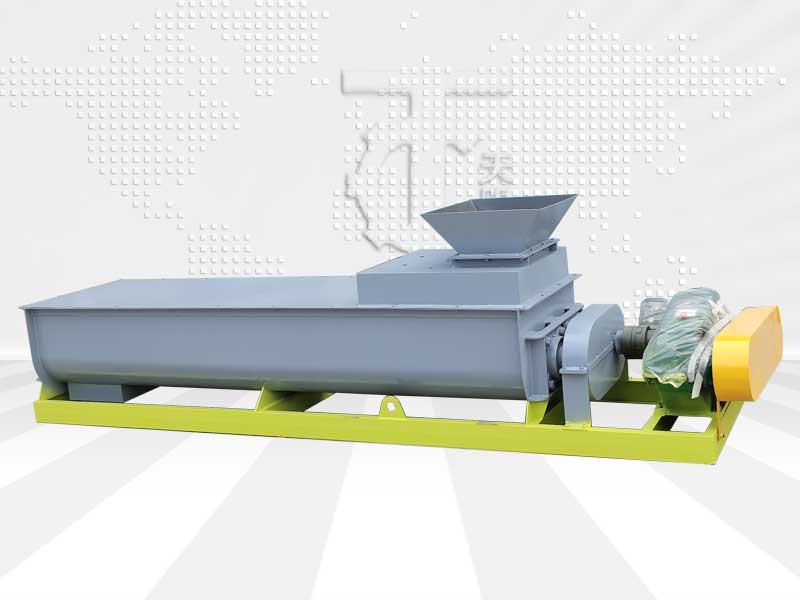

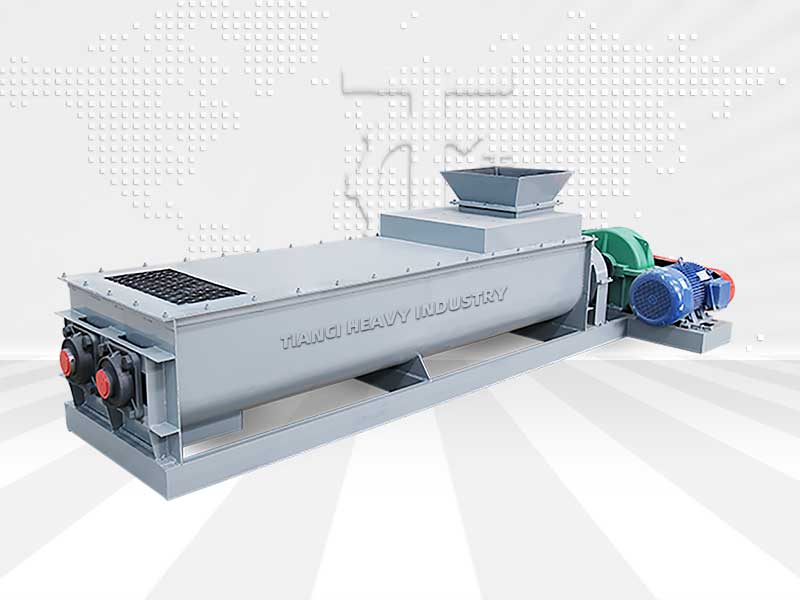

Professional China Fertilizer Mixing Plant - Double Shafts Horizontal Mixer – Tianci

Professional China Fertilizer Mixing Plant - Double Shafts Horizontal Mixer – Tianci Detail:

Applications and Features

1.Product overview

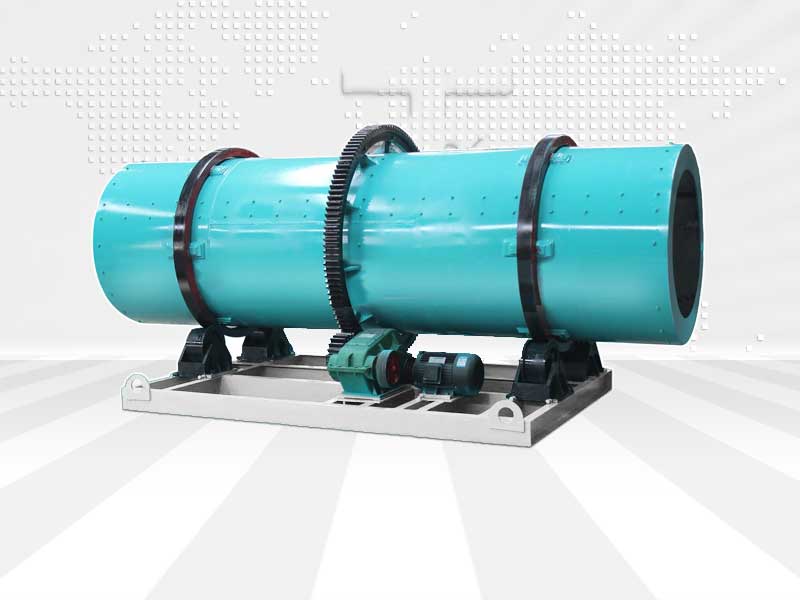

The machine is agricultural machinery research institute use years compound fertilizer processing equipment design, production experience developed in the latest technology products, has obtained the country practical patent. It is used for granulation to all kinds of organic matter after fermentation, break through the conventional organic prilling before granulation needs not to dry and crush the raw materials. It can direct burdening to work out cylindrical grain, can save a lot of energy

2.Equipment characteristics

(1)The product granule is cylindrical

(2) The organic content can be high to 100%, make pure organic granulate

(3)Using organic matter particles with mutual mosaic growing up under a certain force, no need to add binder when granulating.

(4) Product granule is massy, it can sieve directly after granulation to reduce the energy consumption of drying

(5) After fermentation organics don’t need to dry, moisture of the raw material can be in 20%-40%

(6)Forth, Mixing blade welding hard steel tool bit , wear-resisting performance is good, long service life.

Working Principle

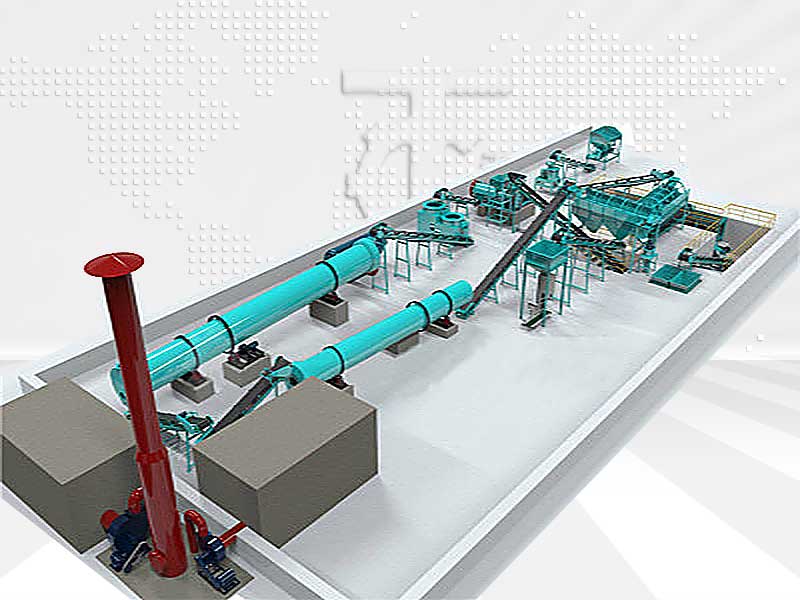

First, the ration of raw powder flows into the mixing tank through feed opening and then water which has been integrated under certain temperature.

Second, using a certain length Shaft through mixing vane to mix up raw powder and then form a nuclear bulge which contains certain moisture.

Third, put the nuclear bulge into the ball plate and stir. The whole stirring divide into atomization area, Stir zone, discharge zone.

Main Technical Parameters

|

Model ZYQ-QZ |

Speed reducer JZQ |

Electric motor |

Spindle speed (Y/mm) |

Rotating diameter (mm) |

Prod Capacity |

Weight KG |

|

400 |

400-1V-2 |

Y160M-4-11 |

52 |

400 |

20 |

2350 |

|

450 |

500-1V-2 |

Y160L-4-15 |

52 |

450 |

25 |

2620 |

|

500 |

500-1V-2 |

Y180M-4-18.5 |

53 |

500 |

30 |

2980 |

|

550 |

650-1V-2 |

Y180L-4-22 |

53 |

550 |

35 |

3450 |

|

600 |

650-1V-2 |

Y200L1-4-30 |

52 |

600 |

40 |

3850 |

|

650 |

750-1V-2 |

Y225S-4-37 |

52 |

650 |

45 |

4260 |

Product detail pictures:

Related Product Guide:

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Professional China Fertilizer Mixing Plant - Double Shafts Horizontal Mixer – Tianci , The product will supply to all over the world, such as: Cyprus, California, Morocco, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178