Product

Full granulation function and high production efficiency

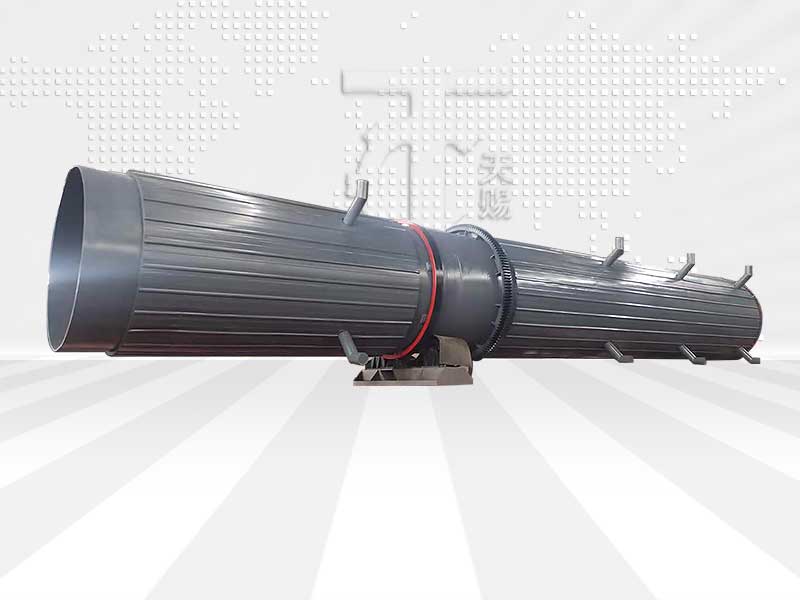

Rotary Drum Dryer-Fertilizer drying and slime drying

Product Introduction

Rotary drum dryer, also known as rotary drum dryer, is a drying equipment, which is widely used in mining equipment. It is divided into direct heat transfer drum dryer and indirect heat transfer drum dryer.

It is suitable for drying magnetic, heavy and floating concentrates of metal and non-metal ores, clay of cement industry and slime of coal mine industry. It is characterized by high productivity and convenient operation. The drum of the rotary drum dryer is a horizontal rotary drum, and various kinds of plates with different staggered angles are welded from front to back. The rotary kiln body is inlaid with different types of refractory bricks according to the needs. The feeding end is provided with a gate ring and a spiral plate to prevent the dumping.

Performance Characteristics

In order to increase the good contact between each part of the material evenly distributed on the cross section of the drum and the drying medium, a lifting plate is installed in the drum. The above various types of lifting plates can be distributed throughout the barrel. In order to ensure that the materials can be sent to the lifting plate quickly and evenly, spiral guide plates can also be installed at 1-5m of the feeding end to avoid the adhesion and accumulation of wet materials on the barrel wall. At the same time, the dried materials are easily lifted up and taken away by the waste gas, and no lifting plate is installed at 1 ~ 2m of the discharge end.

Working Principle

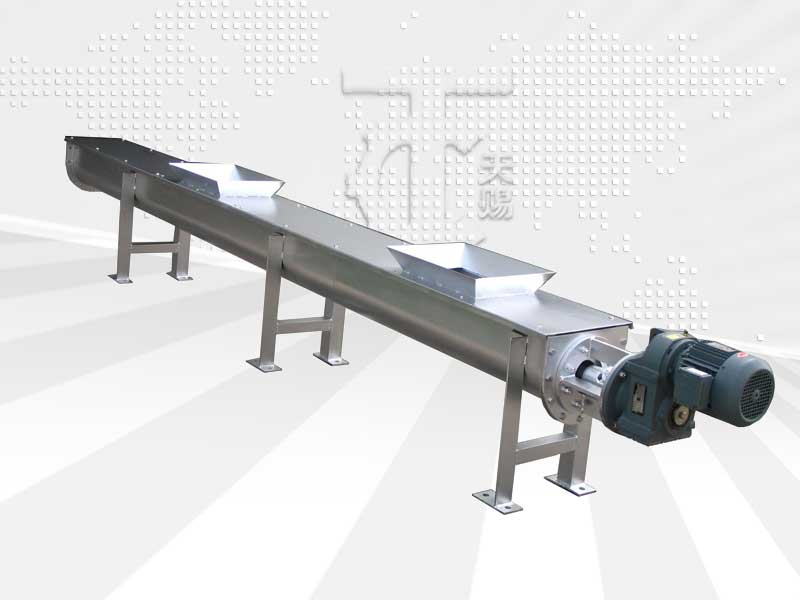

The rotary dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dried wet material is sent to the hopper by a belt conveyor or a bucket elevator, and then fed through the hopper through the feeding pipe into the feed end. The slope of the feeding pipe is greater than the natural inclination of the material so that the material flows smoothly into the dryer. The dryer cylinder is a rotating cylinder that is slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end, and is in countercurrent contact with the material, and the heat carrier and the material are simultaneously flowed into the cylinder. As the rotating material of the cylinder is moved by gravity to the lower end. During the forward movement of the wet material in the cylinder body, the heat supply of the heat carrier is directly or indirectly obtained, so that the wet material is dried, and then sent out at the discharge end through a belt conveyor or a screw conveyor.

Main Technical Parameters

|

Model |

Shell |

Prod capacity |

Inlet temp ofhot air |

Outlet temp ofhot air |

Motor |

Decelevators model |

|||||

|

Inner diam |

length |

inclination |

Rotation speed |

Model |

Power |

Rotation Speed |

|||||

|

mm |

mm |

0 |

r/min |

t/h |

°C |

°C |

|

|

|||

|

ZG12120 |

1200 |

12000 |

2-5 |

4.7 |

2-2.5 |

150-250 |

60-80 |

Y160M-4 |

7.5 |

1460 |

ZQ350 |

|

ZG15120 |

1500 |

12000 |

2-5 |

5.0 |

4-6 |

150-250 |

60-80 |

Y160L-4 |

15 |

1440 |

ZQ400 |

|

ZG15150 |

1500 |

15000 |

2-5 |

5.0 |

5-7 |

150-250 |

60-80 |

Y160L-4 |

15 |

1440 |

ZQ500 |

|

ZG18150 |

1800 |

15000 |

2-5 |

3.9 |

7-10 |

150-250 |

60-80 |

Y200L1-6 |

18.5 |

970 |

ZQ500 |

|

ZG20200 |

2000 |

20000 |

2-5 |

3.9 |

8-14 |

150-250 |

60-80 |

Y200L2-6 |

22 |

970 |

ZQ650 |

|

ZG22220 |

2200 |

22000 |

2-5 |

3.2 |

12-16 |

150-250 |

60-80 |

Y250M-6 |

37 |

980 |

ZQ750 |

|

ZG24240 |

2200 |

24000 |

2-5 |

3.0 |

14-19 |

150-250 |

60-80 |

Y280S-6 |

45 |

970 |

ZQ850 |

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

Project Case

Learn More Join Us

Standardized cemented carbide products have large inventory, customized products can be newly produced and molds are complete.

Get quotation

Get quotation +8613203835178

+8613203835178