Product

Full granulation function and high production efficiency

Wholesale Price China Powder Granules Making Machine - Dynamic Automatic Batching System – Tianci

Wholesale Price China Powder Granules Making Machine - Dynamic Automatic Batching System – Tianci Detail:

Product Description

The dynamic batching machine is suitable for the site of continuous batching,such as fertilizer batching and coking batching.These sites have higher requirements on the continuity of the batching,which generally do not allow the intermediate batching to stop,and the requirements for the proportioning of various materials are strict.The dynamic batching system is usually measured by electronic belt scale or nuclear scale,and the host has PID regulation and alarm function,which can realize the automatic control of a warehouse.

Performance Characteristics

It is suitable for dynamic batching machines such as mixing stations, chemical plants, formula fertilizer processing plants, etc. It has the characteristics of small error, high output and simple operation.

Working Principle

The tape/screw feeder inspects the material passing through the weighing and weighing rack to determine the material quality on the tape; the digital speed sensor at the tail continuously measures the running speed of the feeder; the pulse output of the speed sensor is proportional to the speed of the feeder; the speed signal and the weight signal are one. Take-off and feed into the feeder controller, which is processed by the German microprocessor to generate and display the cumulative/instantaneous flow. The flow rate is compared with the set flow rate, and the frequency converter is controlled by the output signal of the control instrument so as to realize .

Main Technical Parameters

|

Model |

TCDP-3 |

TCDP-4 |

TCDP-5 |

|

Power |

1.1KW*3 |

1.1KW*4 |

1.1KW*5 |

|

Silo size |

1200*1200 |

1200*1200 |

1200*1200 |

|

Precision |

0.5% |

0.5% |

0.5% |

|

Electric control system |

PLC |

PLC |

PLC |

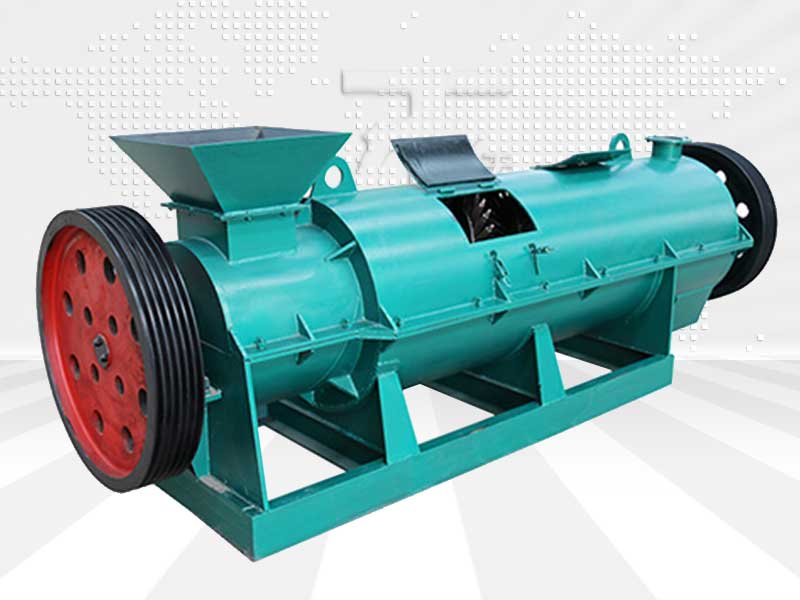

Product detail pictures:

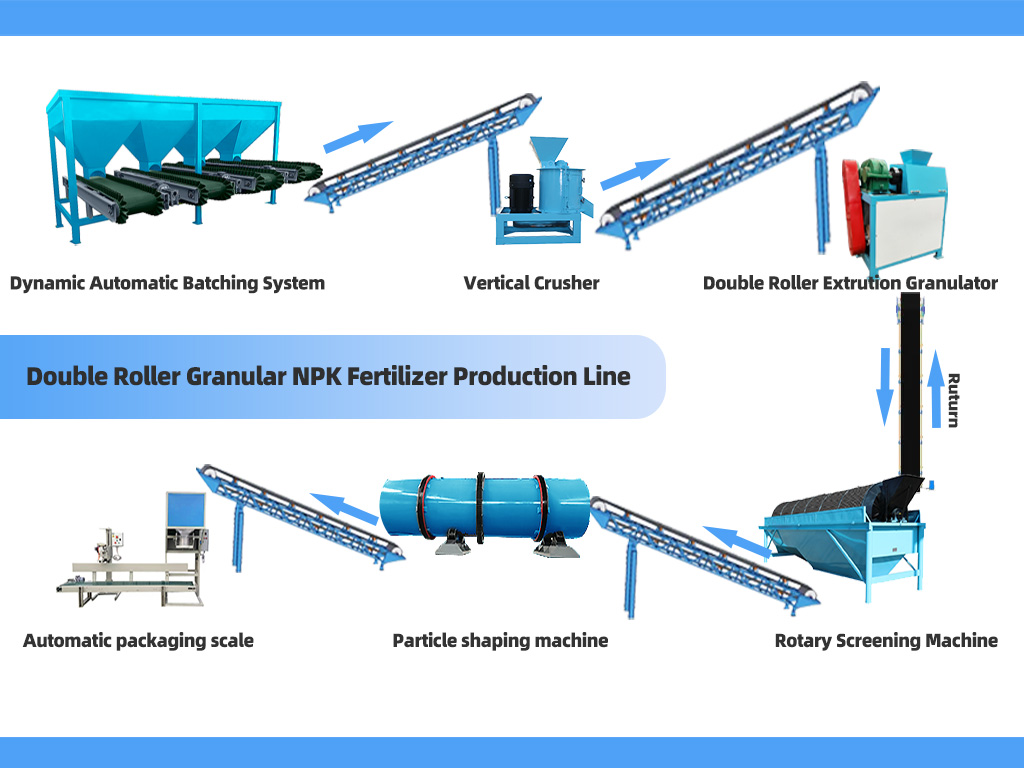

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for Wholesale Price China Powder Granules Making Machine - Dynamic Automatic Batching System – Tianci , The product will supply to all over the world, such as: Madagascar, Ukraine, Casablanca, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Request a Quote

Select model and place orders

Select the model and submit the purchase intention

Get the base price

Manufacturers take the initiative to contact and inform the lo

Plant inspection

Expert training guide, regular return visit

Sign the contract

Select the model and submit the purchase intention

Get the minimum offer free of charge , please fill in the following information to tell us ( confidential information , not open to the public )

If you are interest in our products or need to know more, please click the consultation button on the right

Get quotation

Get quotation +8613203835178

+8613203835178